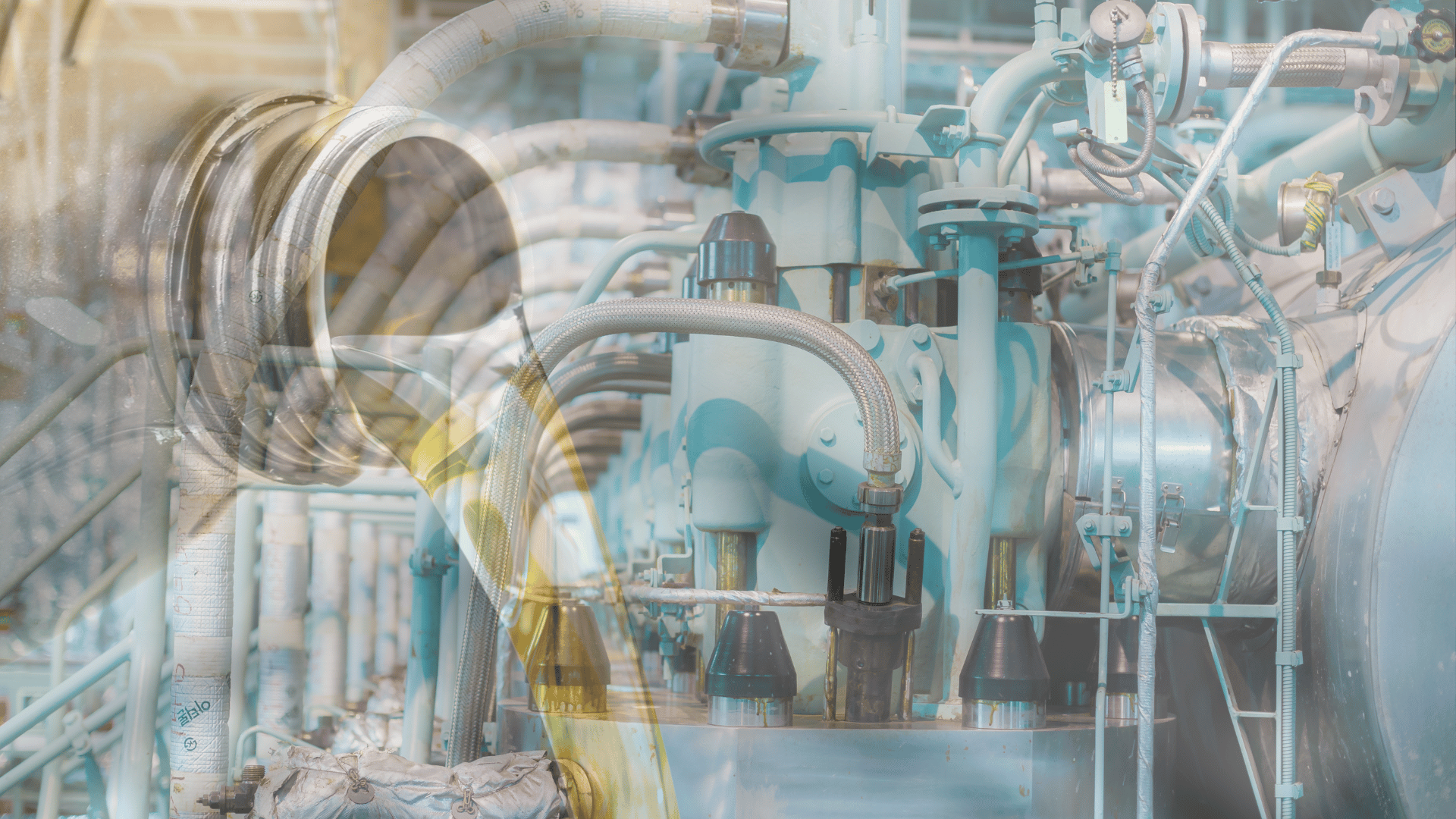

Oil Quality Management Solution (OQMS) is a comprehensive approach to maintaining clean and reliable oil for your equipment. OQMS is essentially about measuring and monitoring the quality of the oil and also continuously cleaning it to keep it free of contaminants and maintain its lubrication efficiency.

With our oil quality management solution, you can detect potential issues before they cause significant harm, ensuring the reliability of both your oil and your machine. By keeping your oil in optimal condition for longer periods, OQMS reduces costs and improves efficiency, ultimately increasing the longevity of the machine.

The oil quality management solution's to the lack of accurate

and reliable sensors, and the need for continuous data analysis to identify changes in oil quality.

Read more

It ensures the oil is of the highest, quality preventing premature

wear and tear on machinery and increasing its lifespan.

Read more

By providing detailed oil quality data and remote accessibility

of oil health data, the solution helps to detect potential issues early, preventing costly repairs.

Read more

The system provides detailed oil quality data based on

several key oil quality indicators, improving maintenance practices and oil analysis capabilities.

Read more

With high-quality oil assurance, it helps to improve machinery

performance and reliability.

Read more

The solution helps to achieve savings of up to 50% on the new

oil expenditure by safely extending oil change intervals beyond conventional norms.

Read more

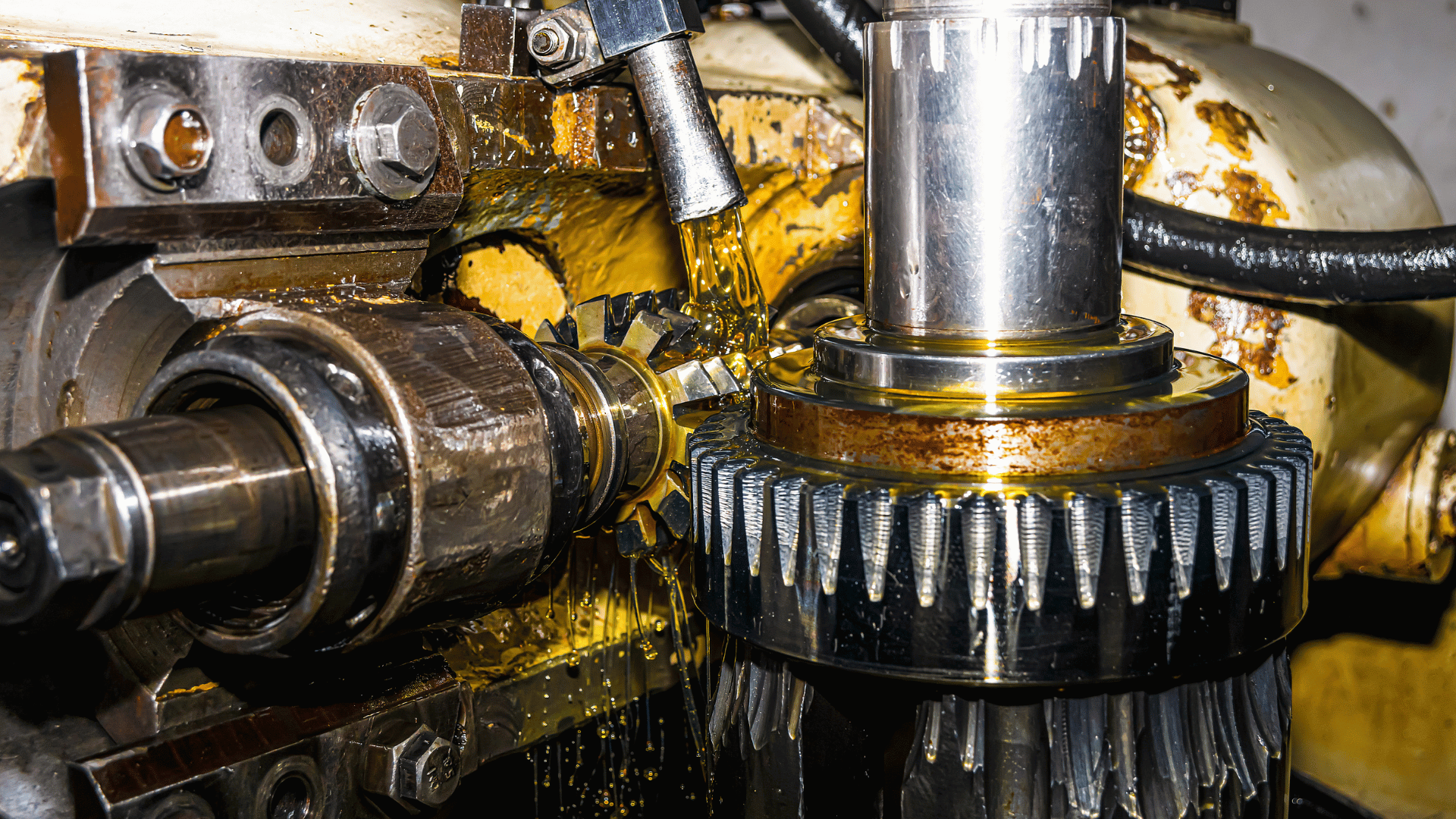

54% of the machine failures can be linked to improper lubrication. Clean oil = proper lubrication = less friction, wear & tear = lesser failure. Lesser failures lead to enhanced life of machinery & components!

The charts below shows the direct correlation between oil cleanliness and the resultant increase in machinery & component life (represented as MTBF – Mean Time Between Failure) These calculations are based on research data published by Noria Corp., USA which is a leading research and training organization in the field of oil management.

Bypass oil cleaning systems are designed to filter out from the

oil as it circulates through the system. However, relying solely on a bypass system to maintain oil cleanliness and quality standards can have limitations.

Read more

Oil oxidation is the process by which oxygen reacts with the

hydrocarbons in the oil, leading to the formation of byproducts such as acids, sludge, and varnish. This process is the nemesis of oil management because it can reduce the performance and lifespan of the oil, as well as the equipment it lubricates.

Read more

The consequences of oil oxidation can be severe and can include

varnish formation, reduced load-bearing capacity, increased particulate matter, and greater wear and tear on equipment. Varnish is a particularly problematic byproduct of oil oxidation, as it can adhere to equipment surfaces, reducing their efficiency and causing them to malfunction.

Read more

Traditional methods of oil quality assessment are

often subjective and rely on visual inspections or lab-based tests, which can be time-consuming and expensive.

Read more

Approximately 56% of engine failures can be attributed to

lubrication-related problems. This highlights the critical role of proper oil quality management in preventing equipment breakdowns and costly repairs.

Read more

Changes in oil quality can a serve as early indicators of engine wear

and emerging faults. However, effectively identifying and interpreting these changes requires consistent monitoring and analysis of oil conditions.

Read more

Oil changes and top-ups are significant expenses in engine

maintenance. Blindly following running-hour-based oil change intervals without considering the actual oil quality can result in unnecessary costs, with expenditures on new oil potentially increasing by 50%.

Read more

The solution's simple installation process makes it easy to

integrate into existing machinery setups.

Read more

The system follows the optimal oil replacement period,

not based on OEM recommendations, ensuring optimal performance of the machinery.

Read more

We offer detailed data on several key oil quality indicators,

giving users a complete picture of their machinery's oil health.

Read more

Our oil health monitoring system provides real-time

data for early detection and prevention of issues.

Read more

Condition Monitoring System offer data on the condition

of the machinery in real-time, enabling quick identification of problems.

Read more

The solution's continuous oil cleaning and in-depth

filtration systems ensure that the oil remains clean and of high quality.

Read more

Our system gives assurance on the highest oil quality,

preventing premature wear and tear on machinery and increasing its lifespan.

Read more

The solution's simple installation process makes

it easy to integrate into existing machinery setups.

Read more

The system follows the optimal oil replacement period,

not based on OEM recommendations, ensuring optimal performance of the machinery.

Read more

We offer detailed data on several key oil quality

indicators, giving users a complete picture of their machinery's oil health.

Read more

Our oil health monitoring system provides real-time data for

early detection and prevention of issues..

Read more

Condition Monitoring System offer data on the condition

of the machinery in real-time, enabling quick identification of problems.

Read more

The solution's continuous oil cleaning and in-depth

filtration systems ensure that the oil remains clean and of high quality

Read more

Our system gives assurance on the highest oil quality,

preventing premature wear and tear on machinery and increasing its lifespan

Read more

Neptunus Power Plant Services Pvt. Ltd.

India

Neptunus Main Office

A 554/555, TTC Industrial Area,

MIDC Mahape, Navi Mumbai,

Maharashtra 400710, India.

UAE

Neptunus Global Trading (NGT)

Ras Al Khaimah Economic Zone,

RAKEZ Al Mamourah Street,

Ras Al-Khaimah, UAE.

France

dataVIB Impédance

80 Dom. de Montvoisin,

91400 Gometz-la-Ville,

France.