Best gearbox services in marine

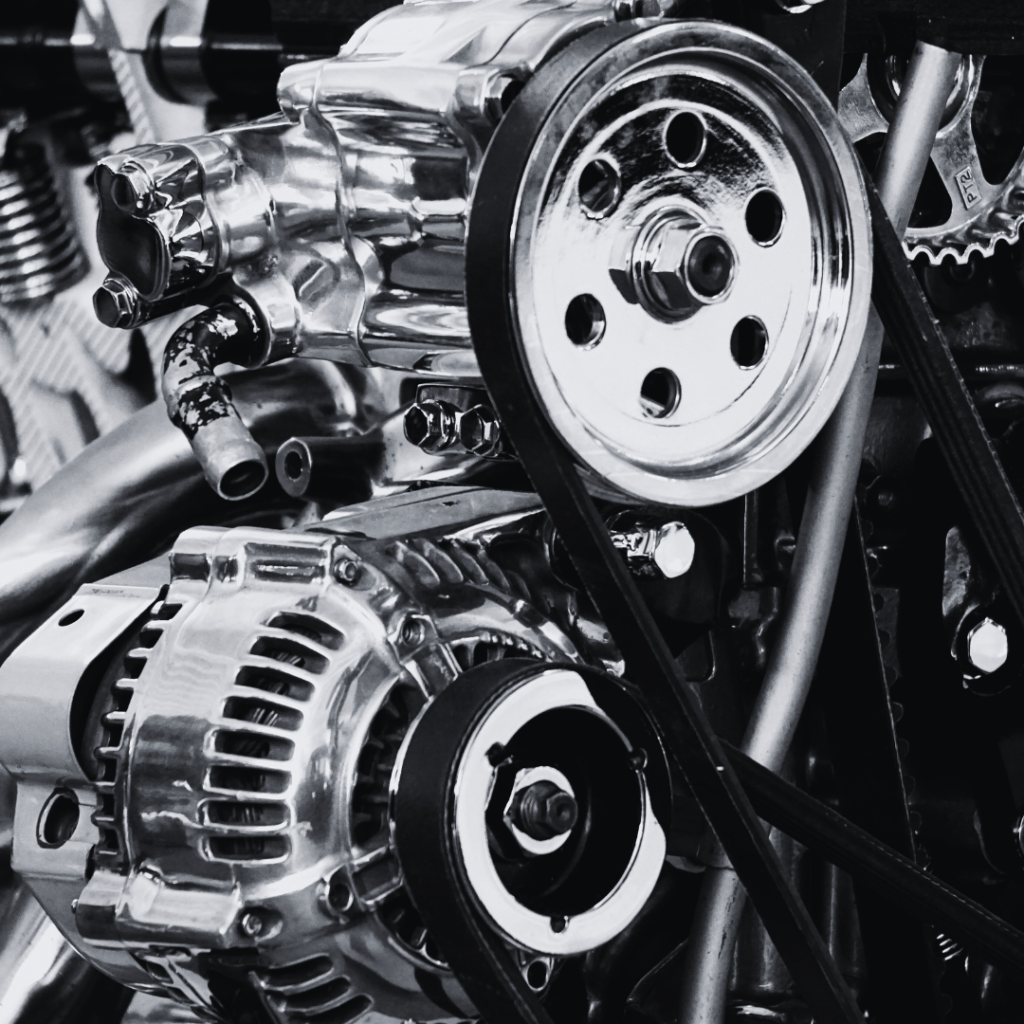

Our marine gearbox repair services stand out for their comprehensive approach, addressing a variety of brands and models. With a commitment to excellence, we not only fix issues but provide a holistic solution for gearbox services in the marine sector.

In addition, we excel in gearbox repair, specializing in addressing gears across various industrial applications, handling bearing failures, and resolving lubrication problems. Furthermore, we offer flexible repair and service contracts, along with expert assembly services for gearboxes.

By deploying cutting-edge technologies approved by industry standards, our objective is clear—to deliver cost-effective, time-efficient solutions that elevate the operational efficiency and lifespan of marine gearboxes.

Send In Your Enquiry for a Quick Quote

Challenges in Marine Gearbox Repair Services

The gearbox repair and maintenance services industry faces several challenges, including the need for rapid technological adaptation to keep pace with evolving machinery and components. The complexity of modern gear systems requires specialists with up-to-date skills, posing a challenge in maintaining a workforce that stays ahead of technological advancements.

Additionally, the demand for cost-effective and sustainable solutions puts pressure on service providers to optimize processes without compromising quality. Striking a balance between traditional craftsmanship and innovative technologies is crucial in addressing these challenges and ensuring the longevity and efficiency of gearboxes in diverse marine applications.

Benefits of Our Gearbox Repair and Maintenance Services

Efficient Turnaround Time

Our ability to complete maintenance tasks quickly means less downtime for your operations, ensuring the continuous and optimal performance of your gearbox asset. With minimal turnaround time, we understand the importance of keeping your gearbox up and running. Read more

Custom Marine Gearbox Maintenance Plans

We tailor marine gearbox repair services specific to your gearbox type, usage conditions, and operational requirements. This customized approach ensures the work done meets your exact needs for ideal functioning after repair. Read more

High

Customer Satisfaction

By delivering on time and with expert quality gearbox repair, our commitment earns long-term customer loyalty and satisfaction. Our reliable track record on past ship gearbox jobs is proof of our dedication to customer service. Read more

Cutting-Edge Technology

Our maintenance integrates cutting-edge technology, employing advanced tools for gearbox health diagnosis and prognosis, ensuring efficient assessments. This commitment enables us to provide accurate insights so that you can take proactive measures. Read more

Experienced Engineering Team

Our team has considerable on-the-job expertise in tackling marine gearbox repair issues efficiently. Their skills and background with gearbox brands guarantee workmanship you can trust for your critical gearbox asset. Read more

Cost-

Efficient Solutions

Our gearbox repair processes are optimized for cost through standardized quality overhaul procedures without compromising on material, parts or manpower allocated per job. This saves significant costs in the long run. Read more

Technical Support by Brand Expertise

Having seasoned gearbox repair specialists in-house allows us to troubleshoot even complex technical issues, ensure correct diagnosis, and enable quick turnarounds through specialized support throughout your gearbox overhaul process. This expertise gives the assurance that repairs are done right. Read more

Send In Your Enquiry for a Quick Quote

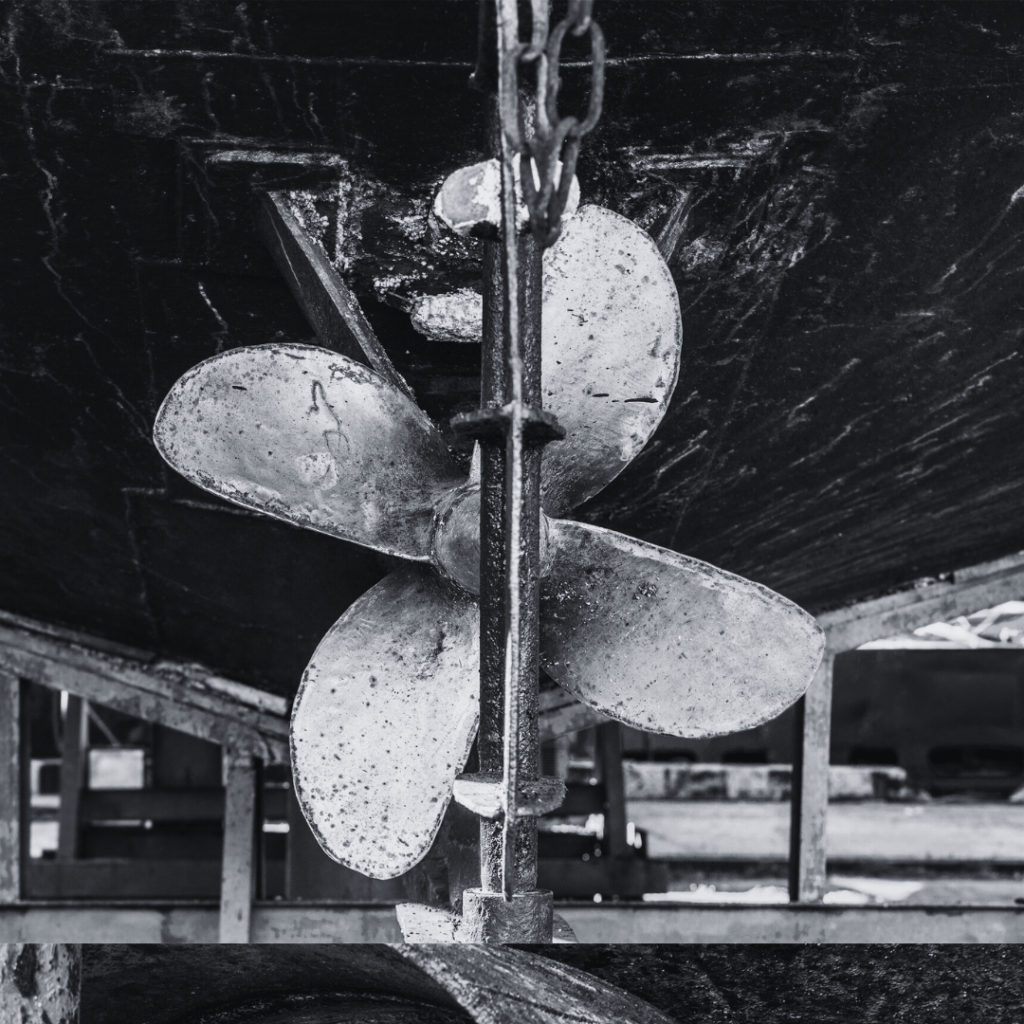

Marine Gearbox Repairs Services

On-Site Gearbox Repairs

Neptunus' in-situ gearbox repair projects bring the expertise of skilled engineers directly to your location, offering a swift and tailored resolution to gearbox issues. Specializing in on-site projects, we ensure efficient solutions seamlessly integrate with your operations, providing convenience and expertise where you need it most.

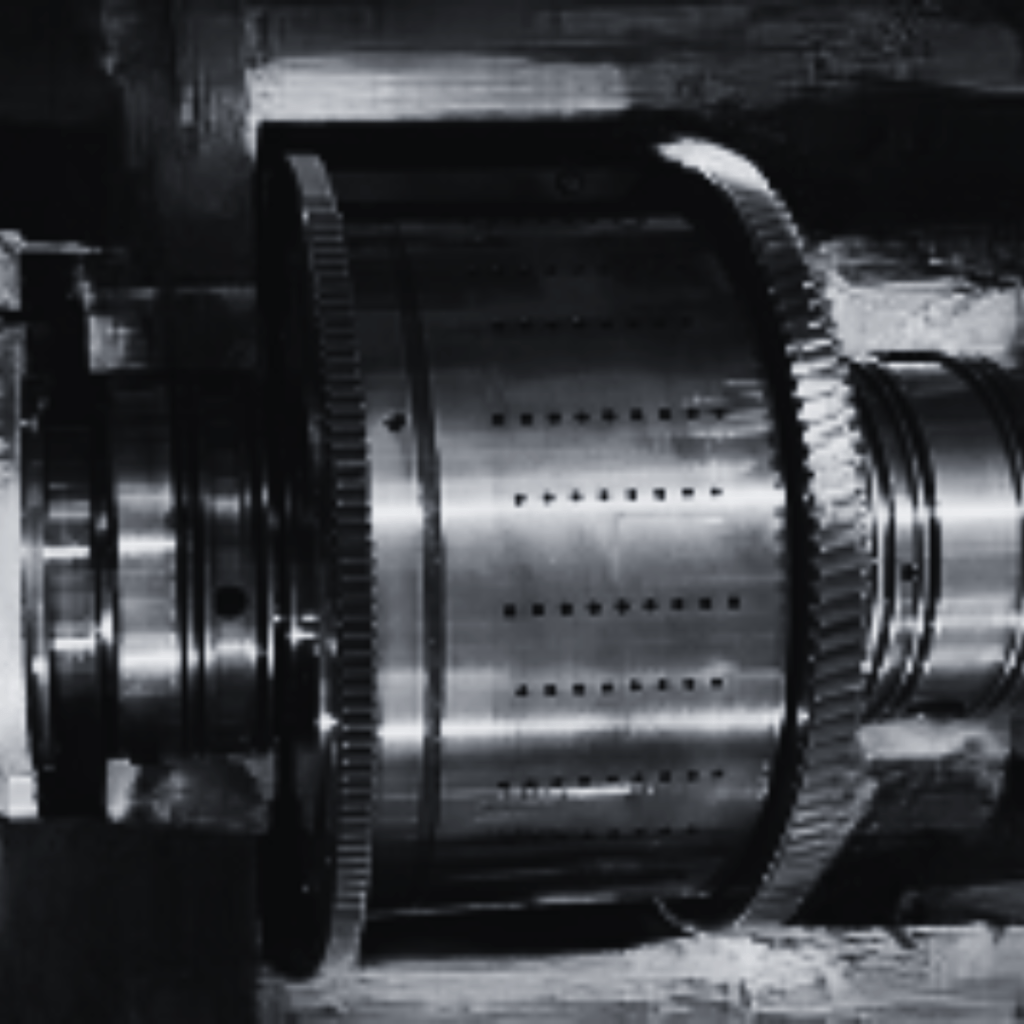

Workshop Gearbox and Component Repair:

Within our workshop, we excel in comprehensive gearbox and component repair services. Our skilled specialists utilize advanced tools and technology to conduct diagnostics, intricate repairs, and quality testing.

Process of Marine Gearbox Repair Services

Step 1: Initial Inspection

We thoroughly inspect all external and internal gearbox components to identify any visible damage or abnormalities early on. This sets the path for repairs.

Step 3: Cleaning and Decontamination

We use specialized cleaning techniques and solutions to remove all contaminants from the disassembled parts. Thorough cleaning enables comprehensive inspection and smooth reassembly.

Step 5: Replacement of Worn Parts

Our team replaces damaged/worn-out components with new, OEM, or high-quality equivalents, as deemed necessary during the inspection. This step restores gearbox integrity and functionality.

Step 7: Bearings and Gear Inspection

Components like bearings and gears are closely examined and tested to verify proper meshing, alignment, and lubrication flow. Correcting identified defects is vital for smooth functioning.

Step 9 : Reassembly

Our technicians methodically reassemble all parts to their original specifications and sequence, ensuring correct alignment and functioning. This precision ensures quality repairs.

Step 11 : Report/Documentation

Every repair step is documented for future reference, along with details on replaced parts, measurements, and reassembly notes. Complete documentation ensures transparency.

Step 13 : Handover and Installation

The expert team takes responsibility for coordinating safe delivery and provides oversight during the reinstallation of the repaired gearbox as the final step. Proper guidelines prevent mishandling and re-damage.

Step 2: Disassembly

Our technicians methodically disassemble the gearbox, clearly labeling and documenting each part to enable tracking throughout the process. This organized approach provides access to internal components.

Step 4: Detailed Inspection

Using calibrated tools, we thoroughly inspect each component to accurately gauge damage, wear, and deviations from manufacturer specifications that require correction. This step is essential for identifying all necessary repairs.

Step 6: Seal and Gasket Replacement

We proactively replace all seals and gaskets with new ones appropriately rated for marine gearboxes to prevent leaks and ensure oil-tight joints. This maintains operational efficiency.

Step 8 : Lubrication

We lubricate all moving parts with manufacturer-recommended lubricants before reassembly to minimize friction during operation. This significantly reduces wear rate and heat generation.

Step 10: Testing and Quality Assurance

The gearbox undergoes rigorous testing on custom test benches simulating marine loads to validate repairs as per performance metrics. This verifies smooth operation before going back into service.

Step 12 : Final Inspection

We re-inspect the gearbox visually and by testing across critical parameters to ensure all issues are addressed before delivery. This is the final quality confirmation.

Send In Your Enquiry for a Quick Quote

We Provide Gearbox Maintenance and Repair Services For The Following Brands

- Niigata (OEM Authorized)

- CAT (Caterpillar)

- EMD (OEM Authorized)

- Wartsila

- Yanmar

- MAN

- MTU

- Detroit

- Wuxi

Send In Your Enquiry for a Quick Quote

Maintenance and Repair Services by Neptunus

Send In Your Enquiry for a Quick Quote

- Marine Diesel Engine Repair Services:

- Marine Diesel Engine Overhaul Services:

- Marine Clutch Maintenance Services:

- Bow-Thruster Maintenance and Repair Services:

- Niigata MRO services for engines

- Caterpillar engine maintenance and repair services

- EMD engine maintenance services

- Yanmar engine maintenance and repairs

- MAN engine maintenance services