strengthening military operations with engine condition monitoring technology

Engine Condition Monitoring For Defence

The defence industry is a vital sector that requires reliable maintenance services to ensure the operational readiness and capabilities of military equipment and vehicles.

Highlights Of Our Product

Made In

India

Easy To Install And Operate

Engine

Agnostic

Pin-Points Emerging Defects

Increased Uptime Of Engines

Remote Monitoring Of All Assets

Simple Faults Attended On The Field.

Scientifically Extend

Overhaul

This encompasses a wide range of assets such as fighter jets, naval ships, aircraft carriers, submarines, tanks, armoured vehicles, and many more. The maintenance of these assets is paramount to ensuring their reliability when carrying out critical missions.

Engine condition monitoring is essential in maintaining the reliability and safety of military assets. Continuous engine monitoring can detect potential issues early, which prevents catastrophic failures that can be risky and jeopardize a mission. In addition, the engine monitoring system’s accurate real-time data on engine health enables decision-makers to make informed choices on the scheduling of maintenance.

Top Challenges Faced In Defence Equipment Maintenance Today

Short meantime Between Overhaul

Logistics And Supply Chain Challenges

Adhering To Time-Based Maintenance

Harsh And Challenging Environments

Absence Of A Reliable Condition Monitoring System

Interoperability

With Other

Systems

Remote Monitoring And Real-Time Data Processing

In the maintenance process of machinery and equipment, the military encounters several obstacles.

The defence machines in general have the shortest mean time between overhauls as recommended by OEMs. Additionally, These machines are deployed in difficult and challenging environments where logistical constraints make it difficult to adhere to the recommended regular time-based maintenance.

In the maintenance process of machinery and equipment, the military encounters several obstacles.

The defence machines in general have the shortest mean time between overhauls as recommended by OEMs. Additionally, These machines are deployed in difficult and challenging environments where logistical constraints make it difficult to adhere to the recommended regular time-based maintenance.

There is no system today that can provide an all-in-one data-driven system that is compatible with all the machinery in their fleet. A solution that can pinpoint faults and predict their health much before deterioration. This would help the commanders in charge to know the exact requirements for their equipment and plan maintenance strategies well in advance.

Neptunus And Indian Defence

Indian Army

Indian Navy

Indian Airforce

Indian Coast Guard

We have been extensively working with Indian Army, Indian Navy, CoastGuard, and Air Force teams since 2018 at Various levels (IHQ- ADB, MCEME, Base Workshop, Armored Workshops, Actual Field team, etc, and Naval Ships like INS Deepak, INS Talwar, INS Shivalik, and ICG Rajdoot; IAC -1) and conducted successful trials on different Vessels and Tanks (BMP-II, T-72, and T 90, ARV), Test beds – UTD 20 and T72 Engine, and in field trial use and in different working conditions to test the robustness and product fitness.

Our vision is to empower the team on the field with our tools, so that periodically or real-time basis field team monitor the deteriorations in performance of these Assets or Engines under a given load condition and use these data as required either to shortlist the best assets in War like situations or To perform required minor/ major maintenance to ensure high reliability. This small initiative not only will ensure higher reliability but also save crores and crores of rupees which otherwise would have been wasted in unnecessary logistics or administrative tasks and increase downtime of the assets.

Our Solution

Our advanced engine condition monitoring solution at Neptunus monitors the health of the machinery and proactively identifies potential issues, allowing for a quick resolution. The system is simple to install, non-invasive and provides an in-situ solution for identifying component-level health issues in any engine with six or more cylinders. It also enables real-time remote monitoring of all assets under a single central command.

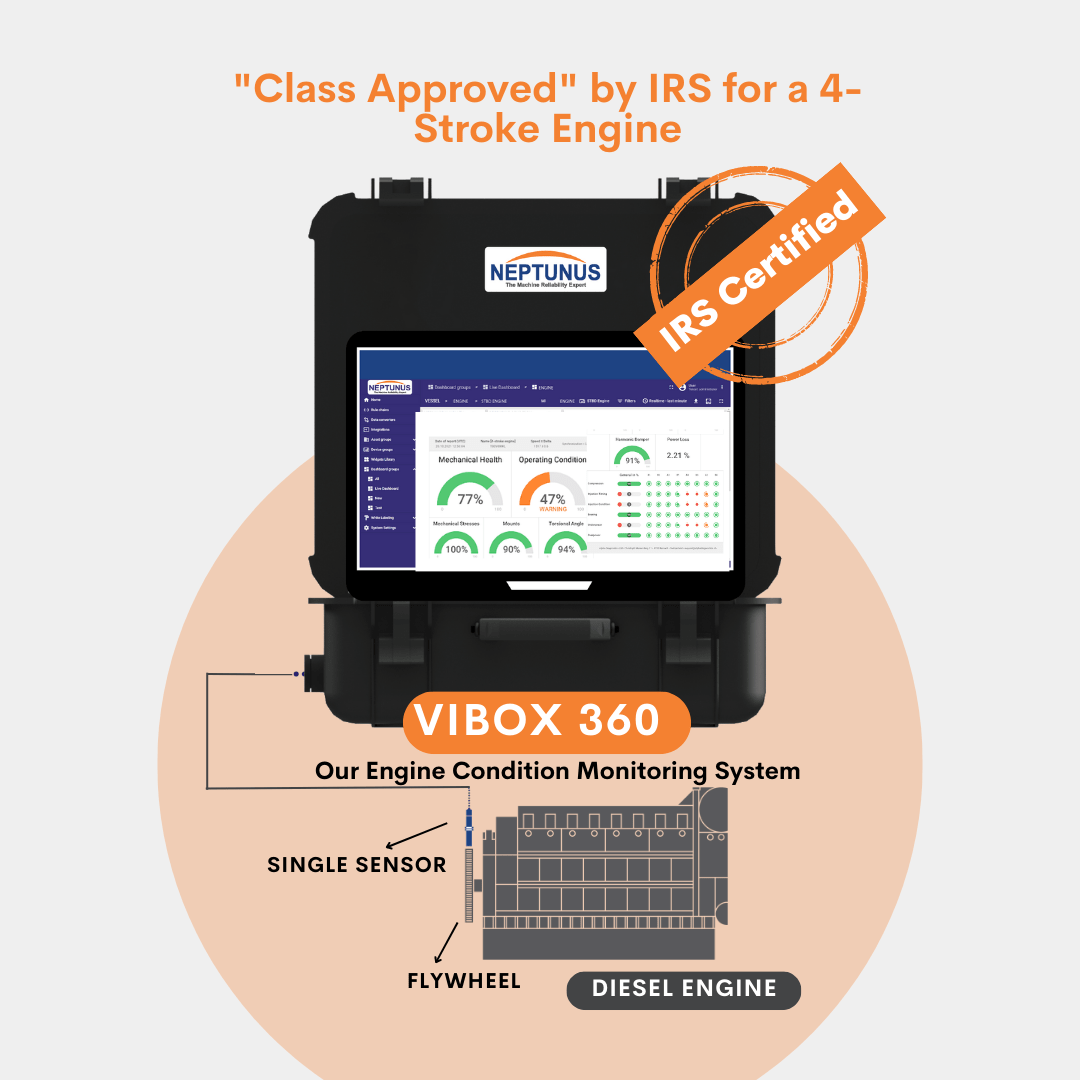

Engine condition monitoring system

Engine condition monitoring system is an advanced, class-approved technology that identifies existing and emerging faults months in advance, giving enough time to prevent any catastrophic unplanned breakdown

About Neptunus

Neptunus Power Plant Service Pvt. Ltd (Founded on 24th June 1996) has over 26+ years of experience in maintenance solutions for foremost oil & gas and marine asset users across India, South Asia, the Middle East, and Europe.