Condition Monitoring System

What Is Condition Monitoring?

Condition monitoring is a maintenance strategy that collects data on the machine’s condition using sensors to detect potential issues. It involves using various tools and techniques to collect data on the machine’s health, such as vibration, oil, and more. This data is then analysed to identify any insights that could indicate a possible issue with the machine.

In simple terms, condition monitoring is the process of monitoring the health of a machine. It is done to detect any changes in its health or condition over time and to diagnose any potential issues before they become serious problems. By doing this regularly, we can catch any problems early on before they get worse and fix them before they cause bigger issues. This helps the machines last longer and work better, which saves time and money in the long run.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Importance of a Condition-Based Monitoring System

Improved Machine Reliability

This method can improve machine reliability as it allows for early detection and diagnosis of potential issues, allowing for maintenance to be carried out before any serious damage is caused. Read more

Improved Productivity

The method is valuable as it increases the productivity of themachine by detecting and solving issues at an early stage, which extends the overhauling period. This enables increasing the uptime. Read more

Reduced Maintenance Costs

It can help to reduce maintenance costs by reducing the number of unnecessary repairs and enabling the correction of existing problems before they become more serious. Read more

Enhanced

Safety

You can also help to enhance safety with this approach, as it makes it possible to identify any safety risks associated with particular machines, allowing for appropriate corrective measures to be taken at the right time. Read more

Prolonged

Asset Life

This is beneficial for extending the life of assets as it assists in preventing major damages that could lead to costly repairs or equipment replacement. This can ensure that the asset remains in good working order for longer. Read more

Reduces The Need For Manual Inspection.

The systems use sensors and other advanced technologies to continuously monitor the condition of machines. This eliminates the need for manual inspections, which can be time-consuming and expensive. Read more

Environmental

Benefits

Condition monitoring can also have environmental benefits by reducing the amount of energy and resources used to maintain machines and equipment. Read more

Features Of The Condition Monitoring System

Real-Time Monitoring:

Condition monitoring systems offer data on the condition

of the machinery in real-time, enabling quick identification of problems.

Read more

Sensor Technology:

Sensors are one of the crucial parts of condition monitoring,

as they collect data on vibration, flow rate, and other parameters. This accumulation of data creates a profile of the machine's health, which helps identify a potential fault.

Read more

Diagnostic Tools:

Diagnostic tools, such as fault detection algorithms,

vibration analysis, and monitoring, are incorporated into the condition monitoring system to improve machine monitoring.

Read more

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Alerts And Notifications:

The condition monitoring system provides alerts

and notifications when potential faults or defects are detected, enabling immediate action.

Read more

Integration with Maintenance Systems:

Condition monitoring is incorporated into maintenance

systems to promptly address any possible faults.

Read more

Continuous Improvement:

Condition monitoring drives continuous development in machinery

by identifying optimization opportunities and helping in the development of maintenance strategies over time.

Read more

How To Get Started With Condition Monitoring System?

Step 1: Define the machine and critical components

Identify the machine and critical components that need to be monitored.

Step 3: Install sensors

Install sensors to monitor the parameters of interest.

Step 5: Analyze the data

Analyze the data to identify any abnormal trends or patterns that may indicate a potential issue.

Step 7: Plan corrective action

Plan the corrective action based on the diagnosis. This may involve repairs, replacements, or adjustments to the machinery.

Step 9 : Monitor the machine

Continue to monitor the machinery to ensure that the corrective action has been effective and that the machine is operating within normal parameters.

Step 2: Establish a baseline

Establish a baseline for the normal operating conditions of the machine and critical components.

Step 4: Collect data

Collect data from the sensors over some time to establish a trend.

Step 6: Diagnose the problem

Diagnose the problem by identifying the root cause of the abnormal trend or pattern.

Step 8 : Implement corrective action

Implement the corrective action and verify that the issue has been resolved.

Step 10: Document results

Document the results of the condition monitoring process, including any corrective actions taken and their effectiveness. This information can be used to improve the process and prevent similar issues from occurring in the future.

Step 1: Define machine

Identify the machine and critical components that need to be monitored.

Step 2: Establish a baseline

Establish a baseline for the normal operating conditions of the machine and critical components.

Step 3: Install sensors

Install sensors to monitor the parameters of interest.

Step 4: Collect data

Collect data from the sensors over some time to establish a trend.

Step 5: Analyze the data

Analyze the data to identify any abnormal trends or patterns that may indicate a potential issue.

Step 6: Diagnose the problem

Diagnose the problem by identifying the root cause of the abnormal trend or pattern.

Step 7: Plan corrective action

Plan the corrective action based on the diagnosis. This may involve repairs, replacements, or adjustments to the machinery.

Step 8 : Implement corrective

action

Implement the corrective action and verify that the issue has been resolved.

Step 9 : Monitor the machine

Continue to monitor the machinery to ensure that the corrective action has been effective and that the machine is operating within normal parameters.

Step 10: Document results

Document the results of the condition monitoring process, including any corrective actions taken and their effectiveness. This information can be used to improve the process and prevent similar issues from occurring in the future.

Why Trend Monitoring Is An Important Aspect of Condition Monitoring

This method involves measuring and analyzing data over time to identify patterns or trends that can indicate deterioration or abnormal behavior in a machine or component. This is typically done using sensors or other monitoring equipment that collects data on various parameters. By monitoring parameters and analyzing the data, technicians can identify changes in performance that may indicate a potential problem. For example, if a machine’s vibration levels steadily increase over time, it may be a sign that the bearings are wearing out and need to be replaced.

Trend monitoring can be a more efficient and effective approach to maintenance compared to other methods, as it enables maintenance teams to identify potential issues by analyzing data patterns and insights. Unlike other methods, trend monitoring relies on a proactive and data-driven maintenance strategy.

Condition Monitoring Techniques

Vibration Monitoring

Vibration condition monitoring measures the frequency and intensity of vibrations in machines to detect defects that may indicate potential issues. This is typically done by attaching sensors to the machine and collecting data on its vibration patterns, which can then be analyzed to identify any changes or deviations from normal operation.

Vibration Monitoring

Vibration monitoring measures the frequency and intensity of vibrations in machines to detect defects that may indicate potential issues. This is typically done by attaching sensors to the machine and collecting data on its vibration patterns, which can then be analyzed to identify any changes or deviations from normal operation.

Oil Analysis

Oil analysis involves analyzing the physical and chemical properties of lubricating oils used in machines and systems to assess their condition and performance. Oil analysis is a key tool for maintenance professionals to assess the health of a machine or system, as it can provide valuable insights into issues such as excessive wear or contamination, allowing for timely maintenance and repairs to be carried out.

Oil Analysis

Oil analysis involves analyzing the physical and chemical properties of lubricating oils used in machines and systems to assess their condition and performance. Oil analysis is a key tool for maintenance professionals to assess the health of a machine or system, as it can provide valuable insights into issues such as excessive wear or contamination, allowing for timely maintenance and repairs to be carried out.

Condition Monitoring System At Neptunus

Oil Condition Monitoring System

The Oil Condition Monitoring System offers real-time monitoring of oil quality through 22 parameters, accurately detecting optimal oil change times and indicating remaining oil life.

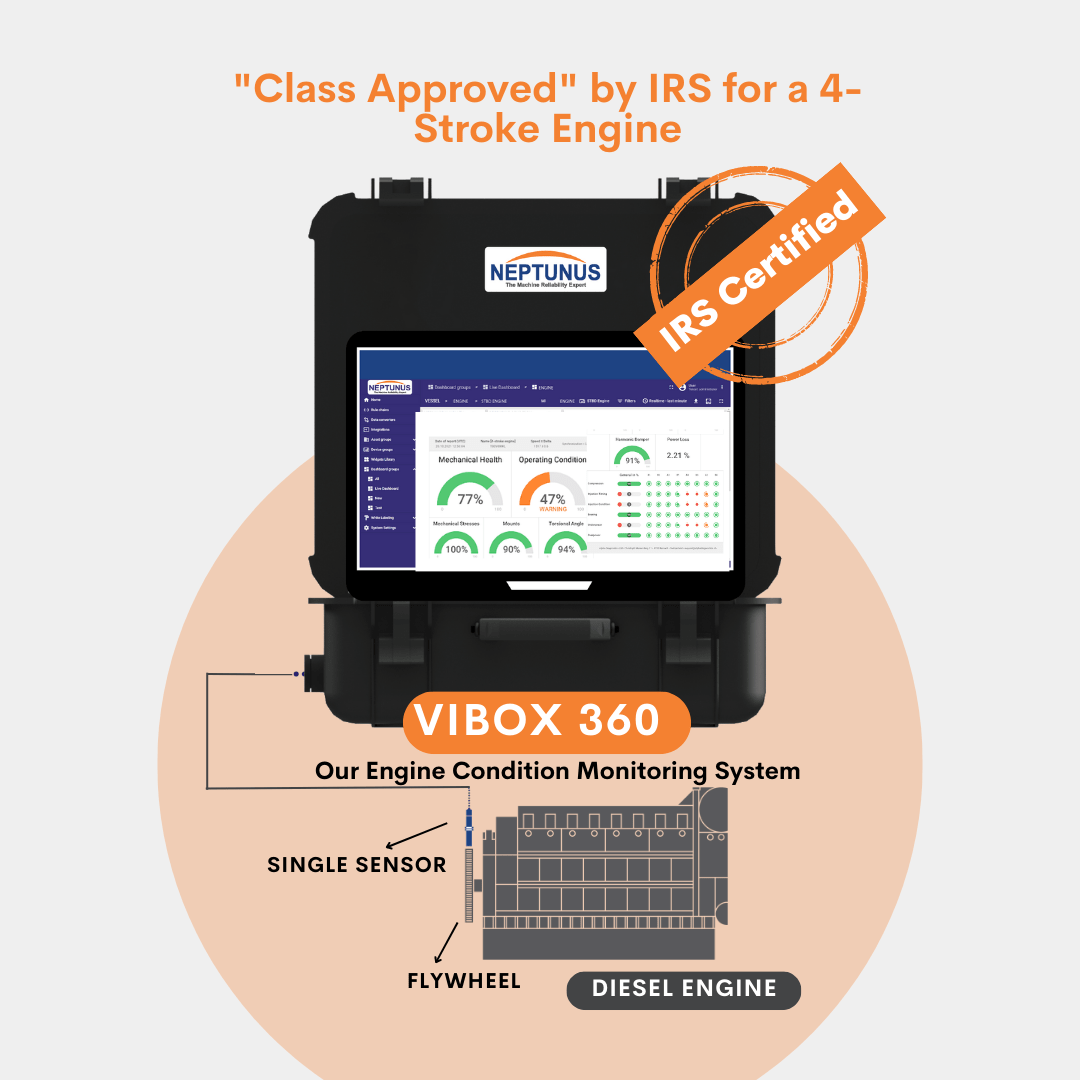

Engine Condition Monitoring System

Class (ABS and IRS) certified technology that helps pin-point defects at a very nascent stage using a single non-intrusive sensor in the customer environment itself.

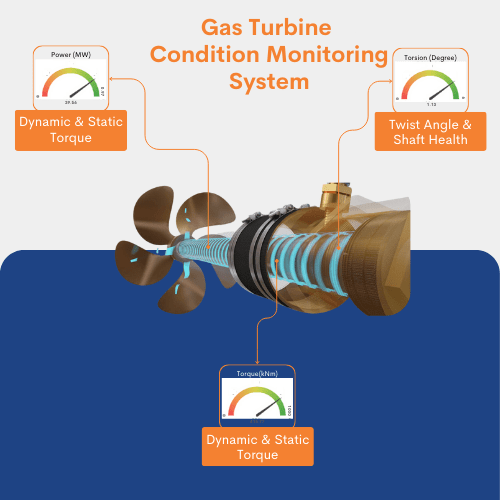

Gas Turbine Condition Monitoring System

The Technology measures Instaneous Angular Speed (IAS) to enable early-stage prediction of turbine health much earlier than other systems.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Why Condition-Based Maintenance Is Better Than Preventive / Planned Maintenance

| Features | Condition-Based Maintenance by Neptunus | Preventive / Planned Maintenance |

|---|---|---|

| Definition | This maintenance strategy involves only 1-2 sensors to detect signs of failure. | Preventive Maintenance is a maintenance strategy that involves scheduling maintenance activities either based on a manufacturer’s recommendation or manual inspection |

| Timing | Our condition-based maintenance approach allows for pinpointing emerging defects and addressing them promptly. | The timing of preventive measures is typically based on the manufacturer’s recommendations or industry standards. |

| Purpose | Condition-based maintenance by Neptunus is designed to eliminate unplanned downtime by identifying faults months in advance. | The purpose is to follow the OEM’s recommendation with the hope to reduce the likelihood of a breakdown. |

| Approach | Neptunus’ maintenance approach based on the condition of machines incorporates remote and in-situ solutions, enabling maintenance teams to monitor asset conditions from a distance or on-site. | This approach follows a predetermined maintenance schedule and involves planned inspections, lubrication, component replacements, and other routine tasks |

| Monitoring Tools | Condition-based maintenance with Neptunus uses a 1-2 MPU sensor, which facilitates easy installation and operation, enhancing the efficiency of the maintenance process. | Planned maintenance relies on manual inspections and periodic maintenance tasks to assess the asset’s condition during routine inspections. |

| Problem Detection | This maintenance strategy helps identify existing and emerging faults at the component level of the engine months in advance. | It typically does not detect potential problems until the machine is already in need of repair. |

| Efficiency | Neptunus’ Condition based maintenance known for its efficiency as it reduces the likelihood of unnecessary maintenance activities. | Preventive maintenance ensures regular maintenance tasks are performed, but it may result in over-maintenance or unnecessary component replacements, leading to higher costs and potential disruption in operations. |

Condition monitoring is an essential part of Machine reliability management. It comes with different applications and purposes, but vibration condition monitoring is highly sensitive to changes in the behavior of rotating machinery, making it an excellent early warning system for potential failures. Our torsional-based engine monitoring system is non-invasive, which means that it does not require physical contact with the machinery being monitored.

Furthermore, our engine condition monitoring system based on torsional vibrations is the first condition monitoring system in the world to be class approved. It is Class certified by the IRS (Indian Register of Shipping) and ABS (American Bureau of Shipping).

You can also check out Vib360 Torquesense: torque and power measurement system.

Apart from the condition monitoring system, we also offer advanced Oil Quality Management Solution, including an oil condition monitoring solution and an oil filtration system. Our advanced oil conditioning system sensor provides a TDN number, which will help determine the health of the oil. Our sensor detects wear particles, contaminants, and changes in oil properties. With the use of oil sensors, real-time data can be obtained without the need to send samples to a lab and wait for a report. Our solution will allow for timely maintenance decisions to be made, reducing the risk of unexpected machine failures. The most important part of asset condition based maintenance is condition monitoring. We offer marine engine and propulsion system maintenance services with our expert service engineers.

With our maintenance service, we are also suppliers of spare parts for engines and propulsion systems. Check out our spare parts offering here .