Oil condition monitoring is the process of assessing the quality of oil used in machinery or engines. This involves monitoring the physical properties of the oil, such as viscosity, acidity, and presence of contaminants, in order to determine the oil’s condition and any potential issues that could affect the performance of the machinery.

Traditional methods of oil quality assessment are often subjective and rely on visual inspections or lab-based tests, which can be time-consuming and expensive. Read more

Monitoring oil quality in real-time can be

challenging due to the lack of accurate and reliable sensors, and the need for continuous data analysis to identify changes in oil quality.

Read more

Oil change schedules are often based on time- based intervals,which do not necessarily reflect the actual condition of the oil. Read more

Integrating oil monitoring equipment into existing machinery can be challenging due to the need for specialized expertise and the risk of equipment damage or downtime. Read more

Existing oil monitoring systems can be costly to implement and continuously monitor the condition of machines. This eliminates the need for manual inspections, which can be time-consuming and expensive. Read more

The Neptunus real-time oil condition monitoring system is designed to monitor the quality of oil used in engines or machines and detect changes. The system is calibrated for a given type of oil and can detect Oil Quality Change Basis 22 Parameters.

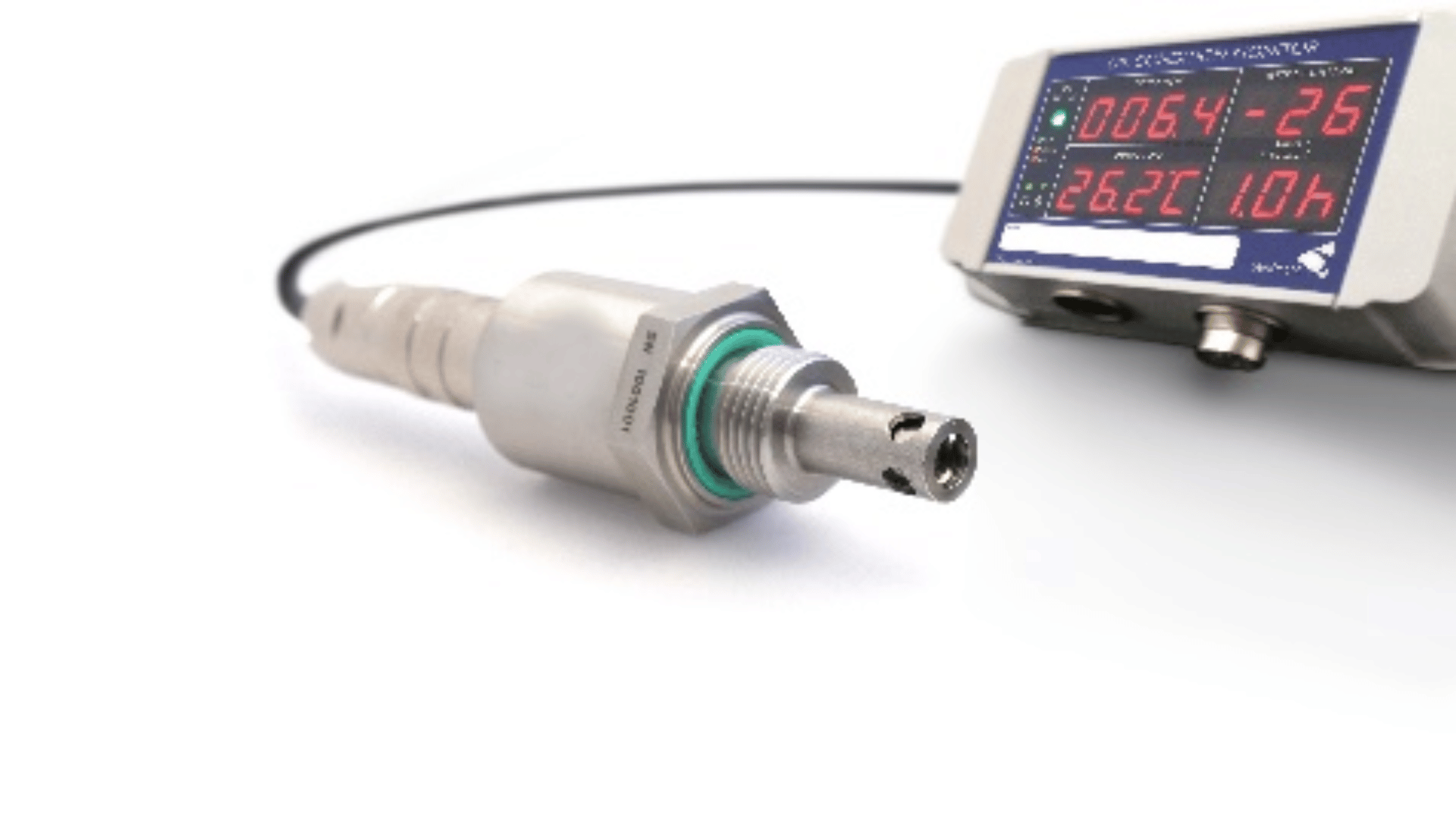

Our oil condition monitoring sensors work on the principle of measuring the dielectric constant of the oil. Any change in any of the parameters of the oil – viscosity, particle contamination, dilution, additive depletion, flash point, etc. will change the constant value and alert the user. Long-term trends can be established, giving the operator insight into the health of the equipment itself. We have seen that as the mean time to overhaul decreases, the oil deteriorates faster.

The approach is simple and most accurate: If the single sensor indicates that the oil is suitable for the manufacturer’s specified hours of operation, no action is needed. Only when the oil deteriorates before the expected timeframe, should samples be drawn and sent for detailed lab analysis.

Our oil monitoring system uses a sensor that continuously monitors the quality of oil in machinery or engines, providing real-time data on the condition of the oil. Read more

The system is able to detect changes in oil

quality basis 22 different parameters, providing a comprehensive view of the oil's condition.

Read more

Based on the state of the oil and the operating circumstances of the machines, the system can accurately decide when it's time to change the oil. Read more

By monitoring the condition of the oil and

detecting potential problems early on, the Neptunus system can help improve the reliability and lifespan of the equipment. This can reduce downtime and maintenance costs over the long term.

Read more

It can identify potential issues before they

become significant by providing real-time data on the status of the oil. This tactic saves time, money, and resources that might otherwise be spent on costly oil-related repairs.

Read more

TDN reflects the overall health of the oil on scale of 1200-0

The higher the number, the better the oil quality. If the TDN reading falls between 1000 to 600, it indicates that the oil is still in good condition.

However, if it falls within the same range but closer to 600, it implies that the oil is worn and in need of replacement. When it drops below 300, the oil is likely to contain debris that can hamper the engine's performance, requiring an immediate oil change.

Read more

Our oil condition monitoring system is able to detect changes in a variety of oil properties, including total base number (TBN), viscosity, moisture, and total acid number (TAN). This allows users to monitor the quality and performance of oil over time and detect any changes that could indicate a problem. Changes in the above parameters are reflected in Tan Delta Number. Read more

The Neptunus system includes a robust sensor that is designed

for use in hazardous environments, such as those with explosive gases or dust. This allows users to monitor the condition of their oil in a wide range of settings.

Read more

Oil condition monitoring provides valuable insights into the health

of oil, with the ability to visualize data in various ways. This includes real-time monitoring through a local display, remote monitoring through Bluetooth connectivity, and comprehensive trend analysis on the cloud.

Read more

With a real-time oil condition monitoring system, you can access oil health data from anywhere, allowing you to keep an eye on the performance of your machinery even when you’re not on site.

The Neptunus system provides users with multiple remote ways to access and view their oil condition data, including on a local display, through Bluetooth connectivity to a mobile device, and on a cloud-based platform.

With our remote condition monitoring it is easy for users to monitor their oil condition data in real-time and make informed decisions about maintenance and repairs.

Neptunus offers a comprehensive approach to oil quality improvement through our Oil Quality Management Solution (OQMS). While we do not sell oil quality sensors as standalone products, we integrate these sensors into our holistic OQMS, ensuring that your oil remains in optimal condition for extended periods.

The first step involves software installation, which is crucial to setting up the system. This step is essential to establishing communication between the system and the user's machine to provide real-time monitoring and ensure that the data collected is accurate.

The first step involves software installation, which is crucial to setting up the system. This step is essential to establishing communication between the system and the user's machine to provide real-time monitoring and ensure that the data collected is accurate.

The second step is calibrating the oil sensor with oil. This calibration ensures that the oil sensor accurately measures the oil's quality and condition, which enables the user to detect any potential issues early on. This calibration is necessary to ensure the accuracy of the system, so the user can make informed decisions about oil changes and maintenance schedules.

The second step is calibrating the oil sensor with oil. This calibration ensures that the oil sensor accurately measures the oil's quality and condition, which enables the user to detect any potential issues early on. This calibration is necessary to ensure the accuracy of the system, so the user can make informed decisions about oil changes and maintenance schedules.

The third and final step is the display unit configuration, which enables the user to view the real-time data collected by the system. This allows the user to monitor the machinery's oil health and detect any potential issues before they become severe.

The third and final step is the display unit configuration, which enables the user to view the real-time data collected by the system. This allows the user to monitor the machinery's oil health and detect any potential issues before they become severe.

Industry Segment: Oil & Gas

Customer: Rig Operator in India

Equiment/Processs: CAT Diesel Engine

Arm Solution: Engine Condition Monitoring

Neptunus Power Plant Services Pvt. Ltd.

India

Neptunus Main Office

A 554/555, TTC Industrial Area,

MIDC Mahape, Navi Mumbai,

Maharashtra 400710, India.

UAE

Neptunus Global Trading (NGT)

Ras Al Khaimah Economic Zone,

RAKEZ Al Mamourah Street,

Ras Al-Khaimah, UAE.

France

dataVIB Impédance

80 Dom. de Montvoisin,

91400 Gometz-la-Ville,

France.