Kidney Loop Oil Filtration System

What is kidney loop filtration?

Kidney loop oil filtration is an oil filtration method used to clean and maintain the quality of oil in machinery and equipment. It operates by diverting a portion of the oil from the main system into a separate filtration loop. Within this loop, the oil passes through various filtration mechanisms. These filters remove contaminants such as dirt, metal particles, and moisture from the oil, ensuring that it remains clean and free of impurities. After filtration, the cleaned oil is returned to the main system, contributing to prolonged equipment life, improved performance, and reduced maintenance costs.

The continuous circulation and purification of oil through the kidney loop system help maintain optimal lubrication properties, mitigate wear and tear, and extend the lifespan of machinery components, making it a vital aspect of industrial maintenance practices.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Challenges Faced In The Maintenance Of Oil Quality

Vague Absolute Or Nominal Filter Ratings

Absolute or nominal filter ratings for oil

maintenance is often imprecise, making it difficult to determine the exact level of filtration needed to maintain consistent oil quality.

Read more

Component Wear And Tear Concern.

If oil maintenance is not carried out regularly , there is a risk of excessive wear and tear of components, which can lead to costly repairs and downtime. Read more

Frequent Oil

Changes

Changing oil too frequently can be expensive and time-consuming, especially if the equipment is in constant use. Read more

Energy Efficiency And Cost Savings

Poor oil maintenance can reduce energy

efficiency and increase costs due to increased friction and heat.

Read more

Minimize Carbon Footprint.

Due to higher energy consumption and more frequent oil changes, inferior oil maintenance can also raise the carbon footprint of a piece of machinery. . Read more

Neptunus’ Kidney Loop Oil Filtration System

Kidney loop filtration systems, also known as offline filtration systems, draw oil from the oil reservoir and deliver it back to the reservoir after filtration. This helps in enhancing efficiency as it operates under below-ideal conditions such as reduced flow, minimal pressure, and no stress from flow and pressure pulsations.

Its continuous operation guarantees uninterrupted equipment functionality, reducing downtime and maintenance costs while extending the lifespan of critical assets. With Neptunus’ innovative technology, industries can rely on consistently clean oil for enhanced productivity and reliability in their operations

Benefits Offered By Our Offline Oil Filtration System

Continuous

Oil

Cleaning

The continuous cleaning oil ensures

that the oil is always in condition. This helps to prevent the buildup of contaminants in the machinery, which can lead to decreased performance.

Read more

In-

Depth

Filtration

Our filtration system is designed to

perform in-depth cleaning of oil, which means that it can remove even the smallest particles from the oil. This is important because even tiny particles can cause significant damage to machinery over time.

Read more

Absolute

Filtration

Till 3µ with >400

Purifies the oil continuously upto 3μ )with ß3 >400 (99.75% efficiency) , along with preventing oil oxidation which results in a minimum of 2x to 5x increase in oil life. Read more

Removes all

Contaminants

Including Water

Our filtration system is not limited to

removing just particulate contaminants like wear debris, dust, and sand; it can also remove water and other fluid contamination, like fuel, from the oil.

This is important because water can cause corrosion and other issues in machinery, which can lead to premature failure

Read more

Increases

Machine

Lifespan

By keeping the oil clean and free of

contaminants, our filtration system can help increase the overall life of the asset and the life of individual components substantially.

Read more

Minimizing Maintenance Requirements

Because our filtration system keeps the oil clean and in optimal condition, it reduces the need for maintenance and downtime. This means that businesses can keep the machinery running smoothly and reduce the costs associated with maintenance and repairs. Read more

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Kidney Loop Filtration System vs. Online Filtration System

| Kidney Loop Filtration System | Online Filtration System | |

|---|---|---|

| Process | Circulates a small amount of fluid from the main system through a filter and back into the main system. | Filters and cleans fluids in real-time as they are being used. |

| Impact On Machine | Does not hinder the equipment’s operation. | Causes resistance for oil flow to equipment’s internal components. |

| Damage To Machine | The offline filtration system doesn’t cause resistance to oil flow inside equipment’s internal components. | Damage to the filtration system or choking of filters can cause oil starvation and seize the equipment. |

| Type | It is an offline filtration system. | It is an online filtration system. |

Process of Kidney Loop Oil Filtration System

The working principle of a kidney loop oil filtration system involves diverting a portion of the oil from the main reservoir, passing it through specialized filtration mechanisms, and returning it to enhance machinery reliability and longevity. The detailed process of the kidney loop (offline) filtration system is as follows:

Step 1: Oil Extraction

The kidney loop filter system begins by drawing a portion of the oil from the main reservoir or sump of the machinery using a pump or other extraction mechanism.

Step 2: Filtration

The extracted oil is then passed through filtration components such as micron filters. These filters are designed to remove contaminants such as dirt, metal particles, water, and other impurities from the oil.

Step 3: Contaminant Separation

Within the filtration system, various techniques are employed to separate contaminants from the oil.

Step 4: Particle Retention

The filtration process traps contaminants within the filter media, preventing them from re-entering the oil stream.

Step 5: Oil Analysis

Some kidney loop filtration systems incorporate an oil condition monitoring system with sensors to monitor and assess the cleanliness and quality of the filtered oil. This step helps in determining the effectiveness of the filtration process and identifying any potential issues with the machinery.

Step 6: Return of Clean Oil

After filtration, the cleaned oil is returned to the main reservoir or sump of the machinery, where it can continue to lubricate and protect the various components.

Step 7: Continuous Circulation

The kidney loop filtration system operates continuously, constantly circulating a portion of the oil through the filtration process to maintain optimal cleanliness and quality.

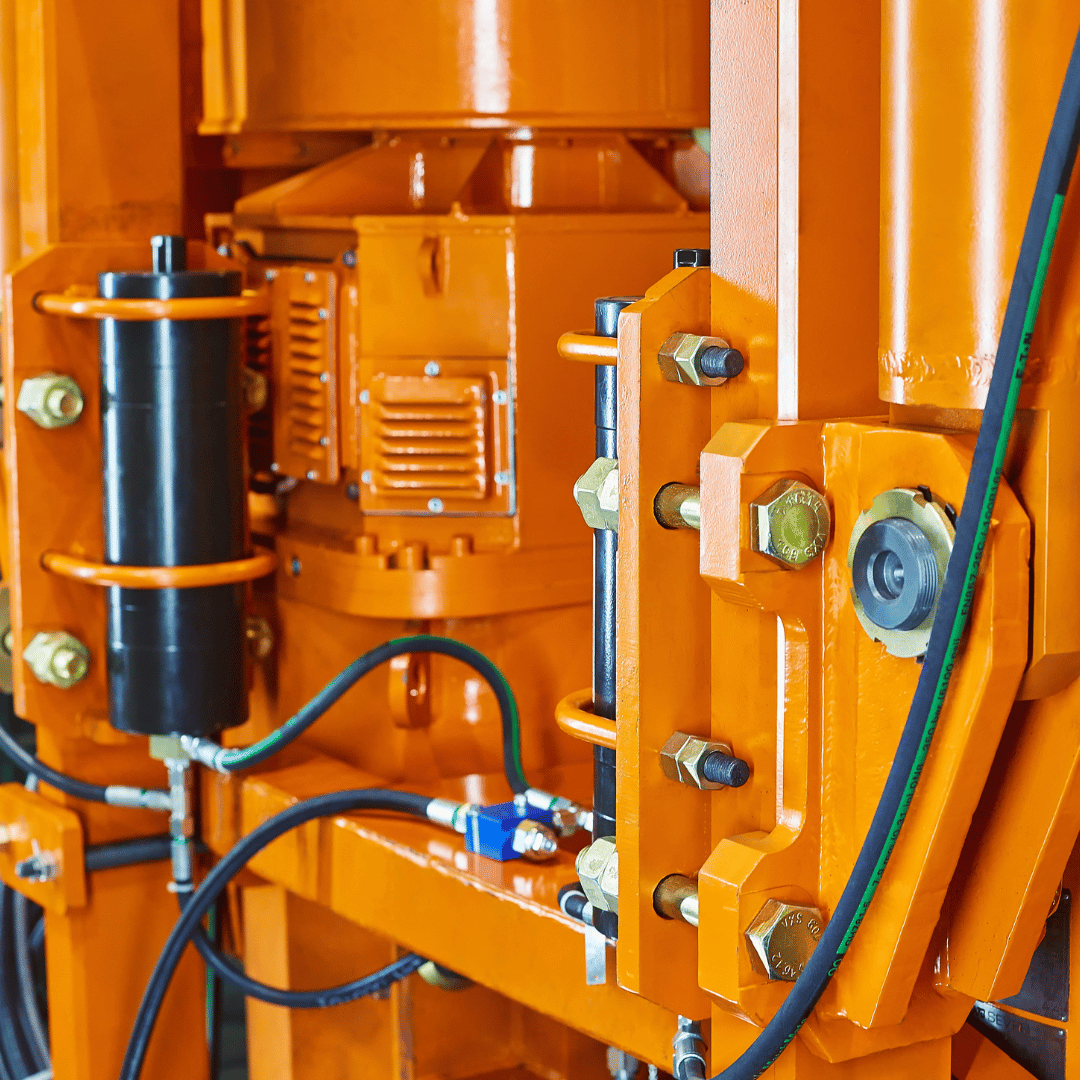

Kidney Oil Filtration Offered by Neptunus

Our oil filtration solution is designed to be versatile, effective on any type of oil in any application, and able to detect all types of wear and contamination. The following are the major applications of our oil filtration system.

Engine

Oil Filtration

System

Hydraulic Oil Filtration

System

Kidney Loop Filtration Models by Neptunus

| MODEL | SE100-ST-1R |

|---|---|

| Oil Sump Capacity | Upto 500 Litres |

| Flow rate | 2 l/m |

| Motor | 230Vx1 or 400Vx3, 50/60Hz |

| Power | 0,12 kW (230V) – 0,18 kW (400V) |

| Thread In/Out | 1/2’’ IN and OUT |

| Element type | 100 size, M – E – X – D – WE type |

| No of elements | 1 |

| Max pressure | Pressure relief set at 6.0 bar |

| Weight kg | 17.4 |

| Dimension mm | 385 x 230 x 460 |

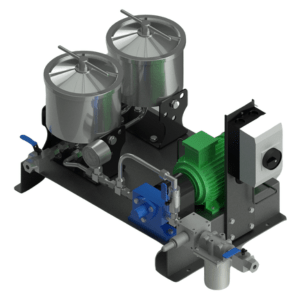

| MODEL | SE100-ST-2R |

|---|---|

| Oil Sump Capacity | 500 – 1000 liters |

| Flow rate | 5 l/m |

| Motor | 230Vx1 or 400Vx3, 50/60Hz |

| Power | 0,12 kW (230V) – 0,18 kW (400V) |

| Thread In/Out | 1/2’’ IN and OUT |

| Element type | 100 size, M – E – X – D – WE type |

| No of elements | 2 |

| Max pressure | Pressure relief set at 6.0 bar |

| Weight kg | 23 |

| Dimension mm | 470 x 400 x 370 |

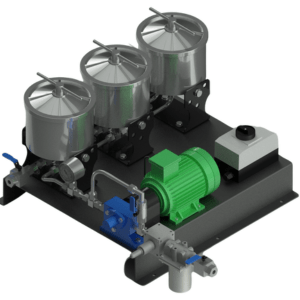

| MODEL | SE100-ST-3R |

|---|---|

| Oil Sump Capacity | 1000 – 2000 liters |

| Flow rate | 5-8 l/m |

| Motor | 230Vx1 or 400Vx3, 50/60Hz |

| Power | 0,12 kW (230V) – 0,18 kW (400V) |

| Thread In/Out | 1/2’’ IN and OUT |

| Element type | 100 size, M – E – X – D – WE type |

| No of elements | 3 |

| Max pressure | Pressure relief set at 6.0 bar |

| Weight kg | 42 |

| Dimension mm | 700*630*470 |

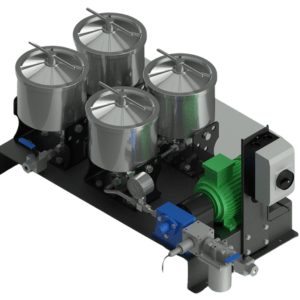

| MODEL | SE100-ST-4R |

|---|---|

| Oil Sump Capacity | 3000 liters and above |

| Flow rate | 8-10 l/m |

| Motor | 230Vx1 or 400Vx3, 50/60Hz |

| Power | 0,12 kW (230V) – 0,18 kW (400V) |

| Thread In/Out | 1/2’’ IN and OUT |

| Element type | 100 size, M – E – X – D – WE type |

| No of elements | 4 |

| Max pressure | Pressure relief set at 6.0 bar |

| Weight kg | 50 |

| Dimension mm | 1043*405*470 |

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

From Prevention to Detection: Our OQMS Addresses the Bigger Problem

Oil filtration systems are essential for maintaining clean oil, but they don’t address the critical issue of detecting problems in the oil or the machine components it lubricates. Without effective detection, machines can suffer severe damage, leading to costly repairs and downtime.

That’s where our Oil Quality Management Solution (OQMS) comes in Picture.

With OQMS’ oil condition monitoring, you can detect potential issues before they cause significant harm, ensuring the reliability of both your oil and your machine. OQMS is the ultimate solution for increasing the longevity and efficiency of your equipment while reducing maintenance costs.

Trend monitoring can be a more efficient and effective approach to maintenance compared to other methods, as it enables maintenance teams to identify potential issues by analyzing data patterns and insights. Unlike other methods, trend monitoring relies on a proactive and data-driven maintenance strategy.