Engine Condition Monitoring System

Engine Condition Monitoring System Based On Torsional Vibration by Neptunus

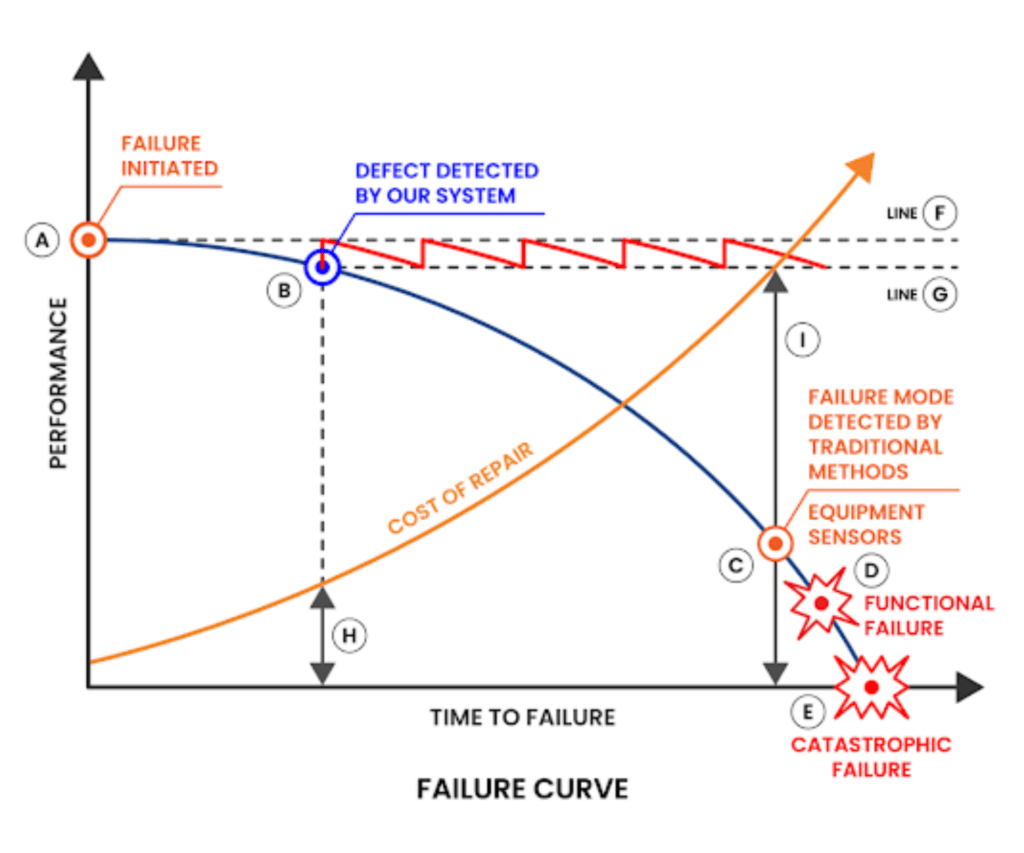

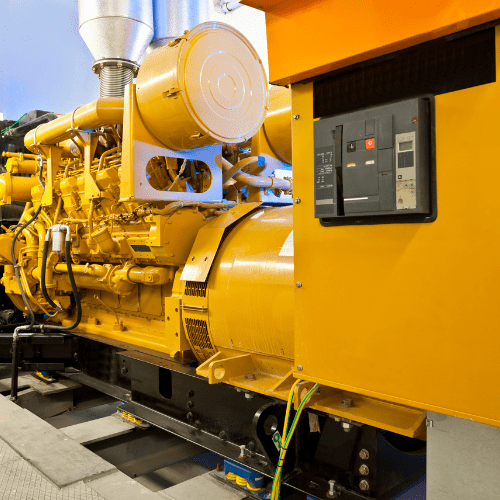

The Engine Condition Monitoring System (ECMS) is a non-intrusive condition monitoring technology that predicts engine health and defects much earlier than all other systems. This is achieved with the help of instantaneous angular speed obtained by measuring speed.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

How does ECMS work?

Defects in an engine generate non-uniformity in the rotation (torsional vibration) of the crankshaft, which can be measured on the flywheel by the installation of a single non-intrusive speed sensor (a magnetic pickup sensor). This helps to assess in detail the mechanical behavior of the engine and its operating condition by diagnosing injection, compression, or valve state defaults, as well as bearing and moving parts damages.

How does ECMS work?

Defects in an engine generate non-uniformity in the rotation (torsional vibration) of the crankshaft, which can be measured on the flywheel by the installation of a single non-intrusive speed sensor (a magnetic pickup sensor). This helps to assess in detail the mechanical behavior of the engine and its operating condition by diagnosing injection, compression, or valve state defaults, as well as bearing and moving parts damages.

What Sets It Apart From Its Competitors?

Class-certified by ABS and IRS

Pin-Point Cylinder Level Faults at the Very Nascent Stage

Works for Engines of Any Brand or Model

Requires Only a Single, Non-Invasive Sensor

In-situ (Customer Environment) As Well as Remote Monitoring Are Available.

Integrate data from other sources into a single platform.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

How does it help you?

Avoid Unplanned Shutdowns And Breakdowns.

Shift To Condition-Based Maintenance From Scheduled Maintenance

Achieve Significant Savings In Lifecycle Costs

Reduce The Carbon Footprint.

Overcome The Logistical Challenges Of Procuring Spare Parts And Skilled Manpower.

Take Independent Decisions Without The Need For A Certified Expert.

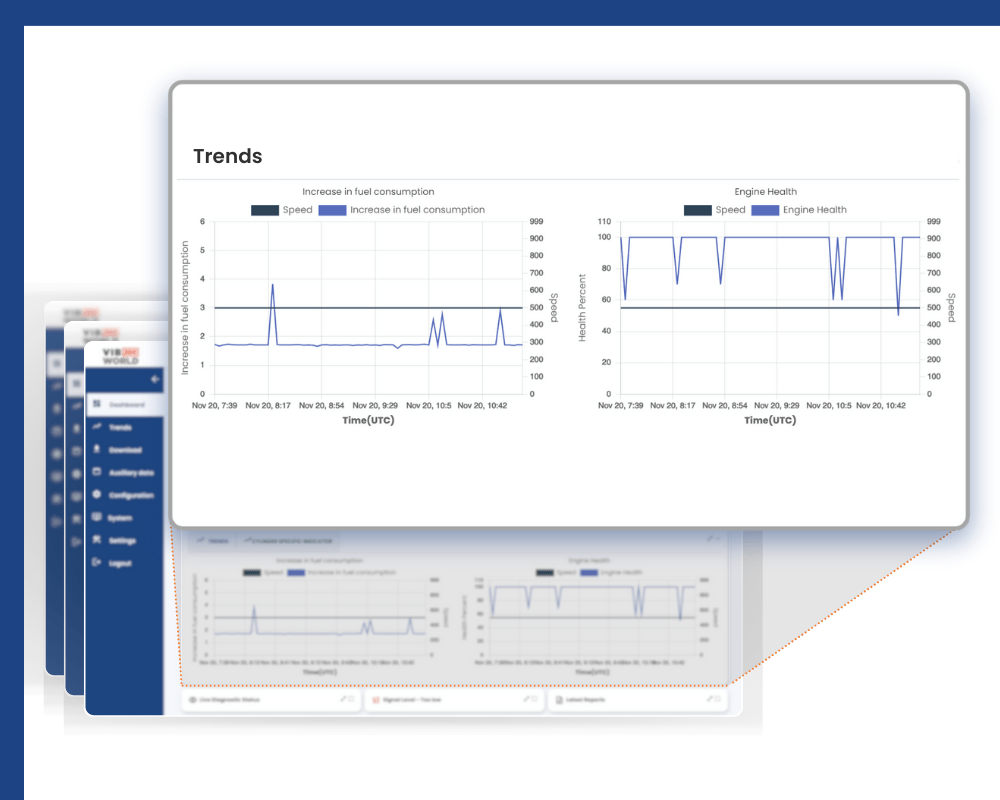

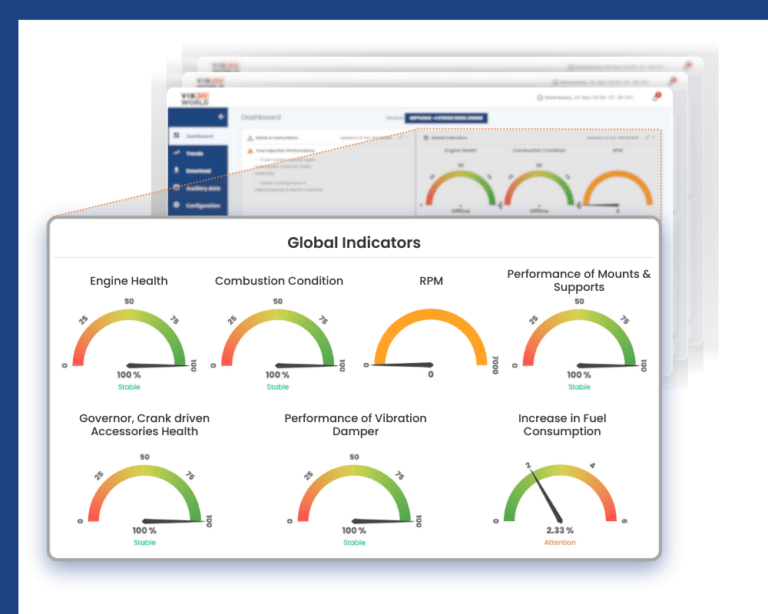

Insights From Our System

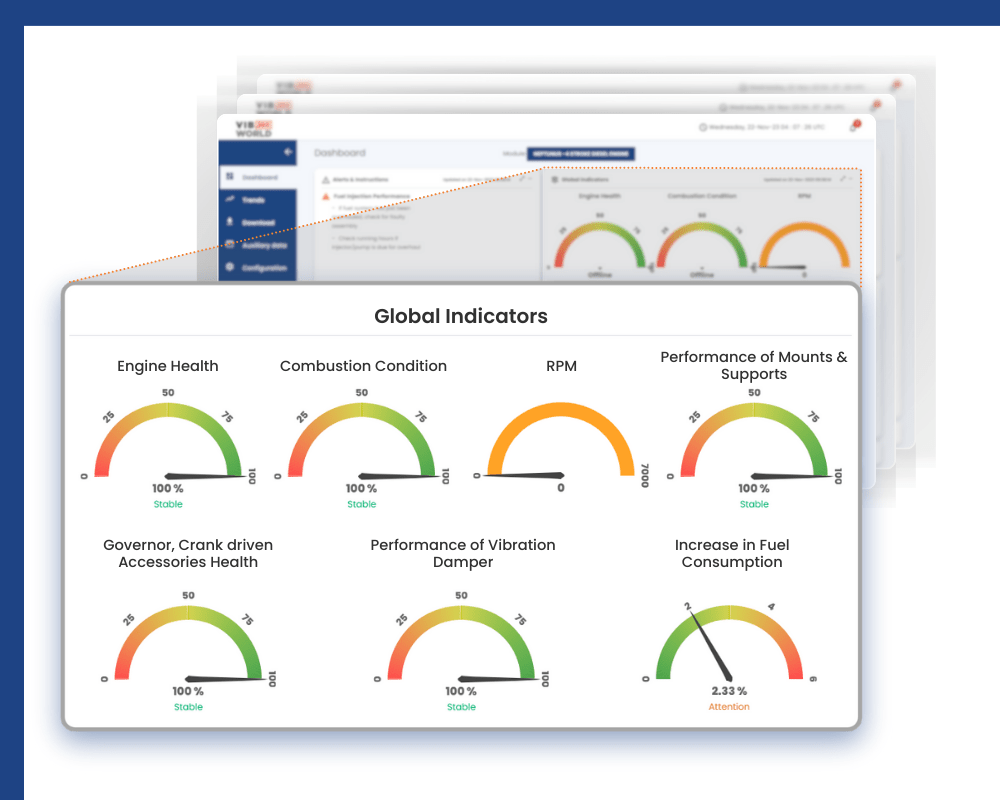

1. Global Indicators

Global indicators will indicate instantaneous readings for the given operating condition.

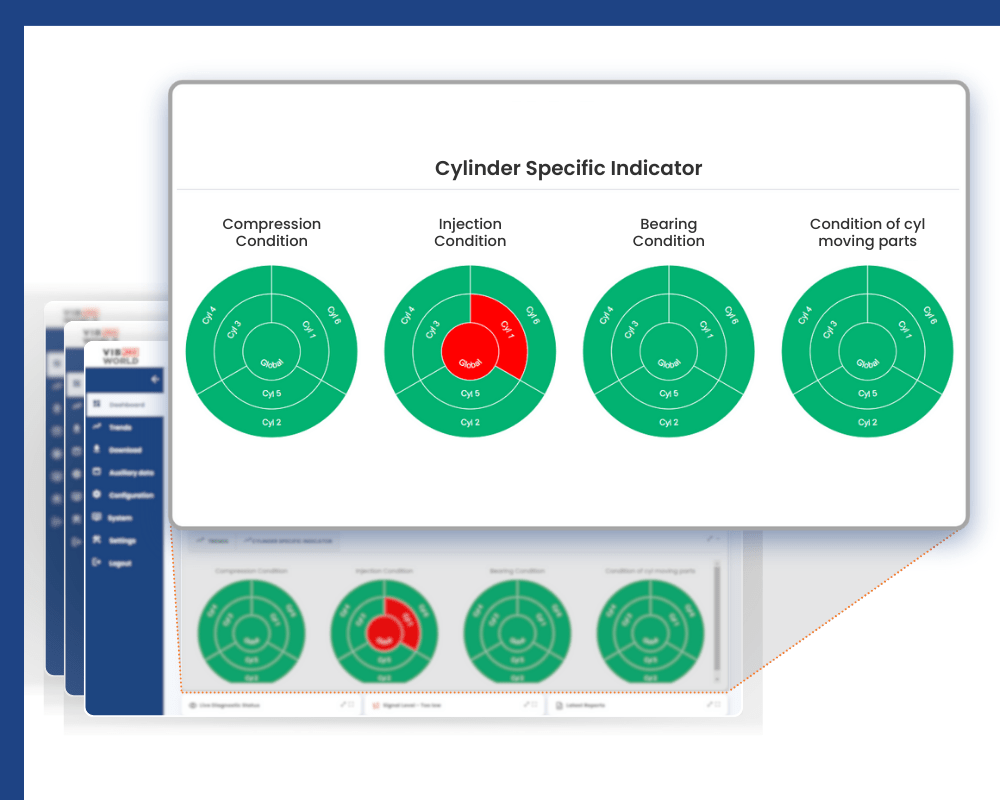

2. Cylinder Specific Indicators

Cylinder Specific Indicators provide instantaneous unit-specific injection, bearing, compression, and moving parts conditions of individual cylinders for the given operating conditions. This is used to identify the health of cylinders in pairs in case of TDC ( Unit tagging is done by taking signals from the flywheel for a 4-stroke engine) tuning.

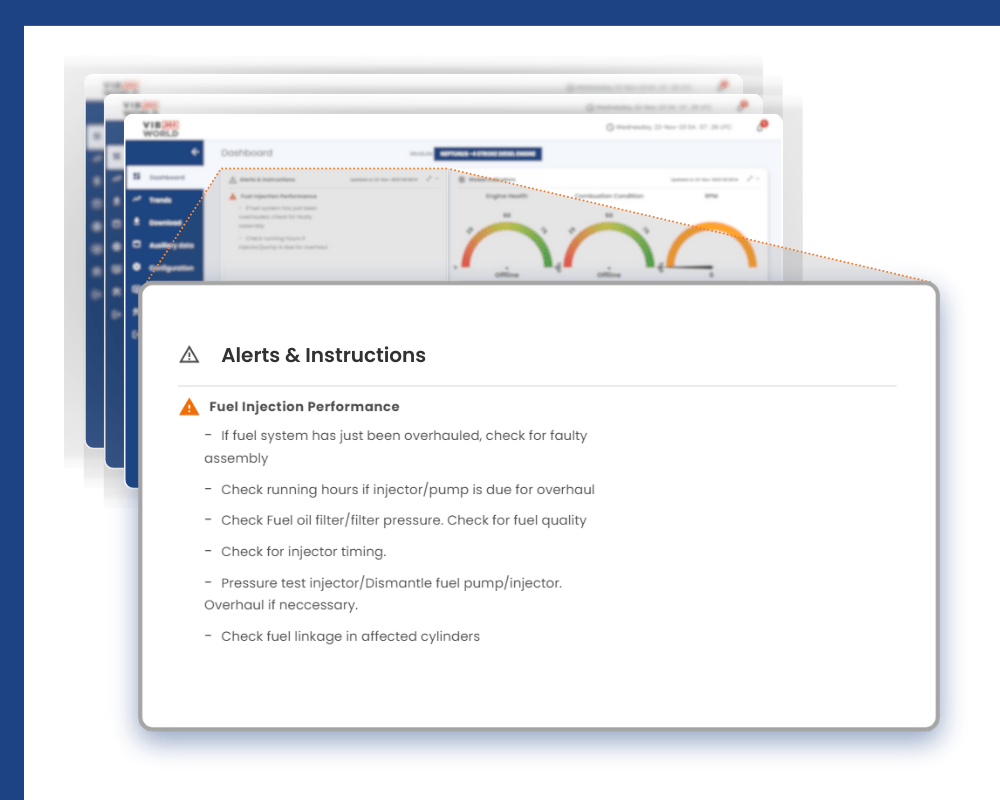

3. Alerts & Instructions

This information is a summary of recommended actions based on the nature of the operation for the operator to either be aware of or to act.

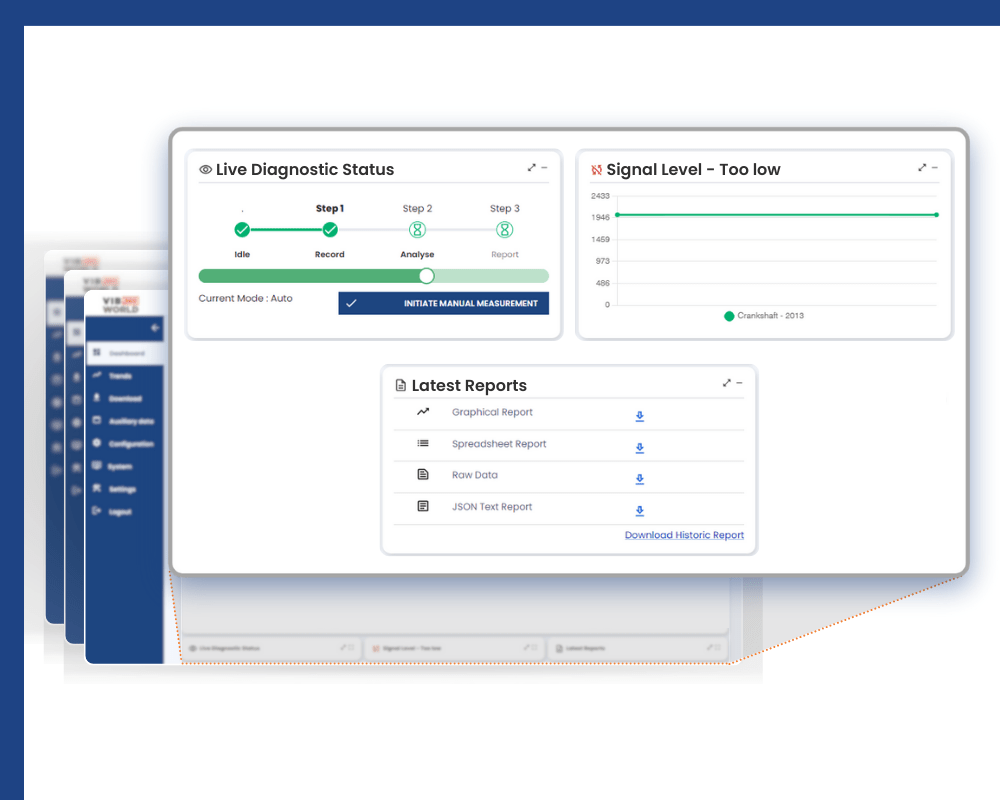

5. Live Diagnostic Status :

It indicates the processor status when processing the input right from data recording.

6.. Signal Status:

It indicates synchronization information between two sensors when needed

7. Latest Reports:

The last processed Report can be downloaded in different formats such as Graphic, Spreadsheet, Raw Data, and JSON text as seen below. For extensive downloading one can visit the “downloading” tab from the side bar.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

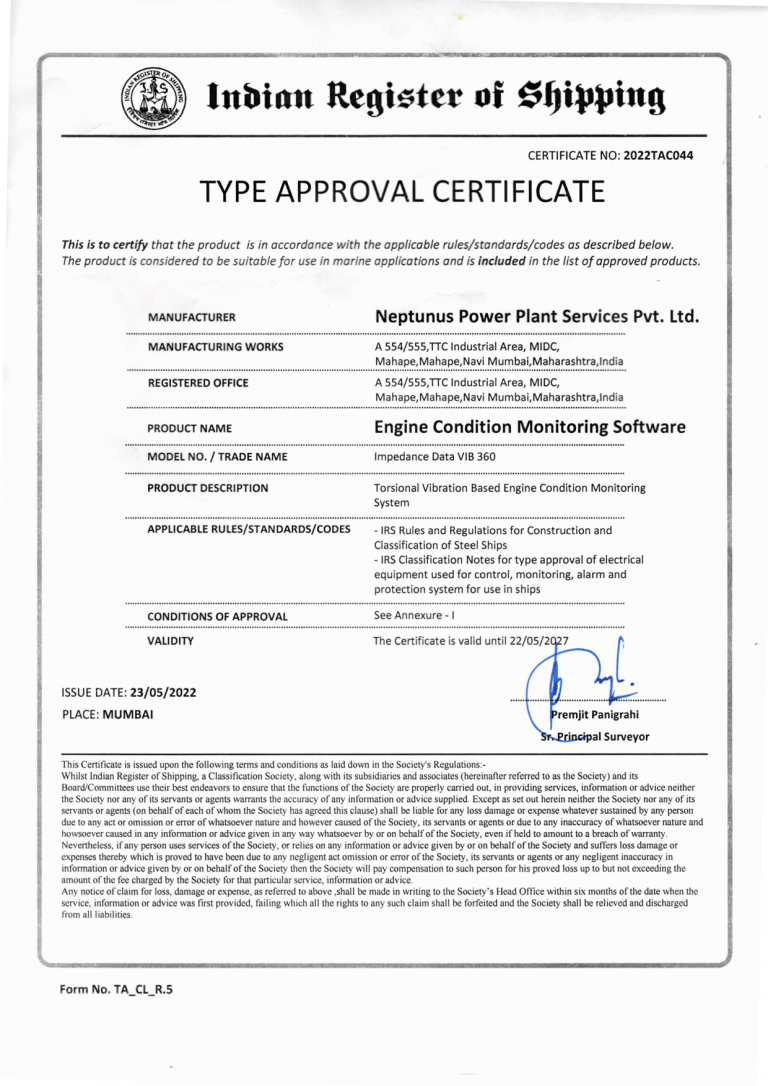

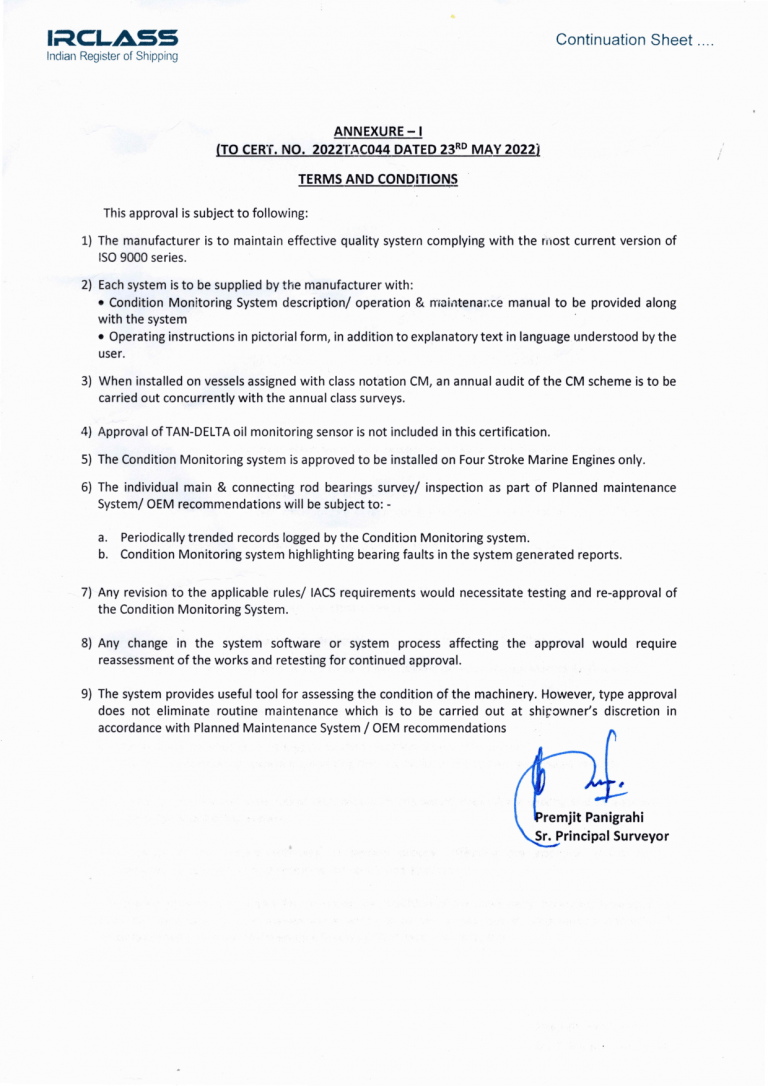

Our Engine Condition Monitoring System is Type-Approved by IRS & ABS

Neptunus engine condition monitoring software solution has received A Type approval from the Indian Register of Shipping (IRS)

- Asset owner can follow more effective condition-based maintenance rather than OEM recommended time-based maintenance

- The IRS-approved system helps in extending the major overhauls

- The solution can guide to do minor overhauls to avoid catastrophic failure and to increase fuel efficiency

- Assets monitored with a class-approved system has a good resale value

Applications Of Neptunus' Condition Monitoring system

By optimising the utilisation of spare parts during maintenance and boosting machine dependability, Asset reliability in maintenance contribute to the achievement of sustainability goals. Businesses that practice effective asset management can reduce downtime, increase equipment dependability, and utilise fewer resources overall. This approach calls for regular monitoring of machine performance, early detection of problems, and the use of preventative maintenance techniques to fix problems before they get worse. Businesses can reduce their environmental impact and increase operational efficiency by implementing asset reliability management systems.

For assets like engines and gas turbines, Neptunus’ cutting-edge Condition Monitoring the marine engine monitoring system, and the gas turbine vibration monitoring, are crucial because they maximise maintenance scope, spot issues early, and provide condition insights.

Remote condition monitoring plays a pivotal role in ensuring these benefits by allowing continuous oversight and early detection of faults. In the age of sustainability,Oil Quality Management has emerged as a critical component of asset dependability management programmes due to its vital function in extending asset life. kidney loop oil filtration and oil condition monitoring are combined in the Oil Quality Management Solution for optimal lubrication performance. By monitoring the quality of the oil they use, organisations may further improve the operation of their equipment.