Condition Monitoring for Diesel Engine

Diesel engines are widely used in various industries, including marine, transportation, construction, and power generation, due to their durability, fuel efficiency, and high torque output. Effective maintenance is crucial for ensuring optimal performance, reducing downtime, and extending the engine’s lifespan. However, like any mechanical system, they are susceptible to wear and tear, which can lead to unexpected breakdowns and costly repairs. This is where diesel engine condition monitoring systems come into play, providing real-time insights into the engine’s performance and health.

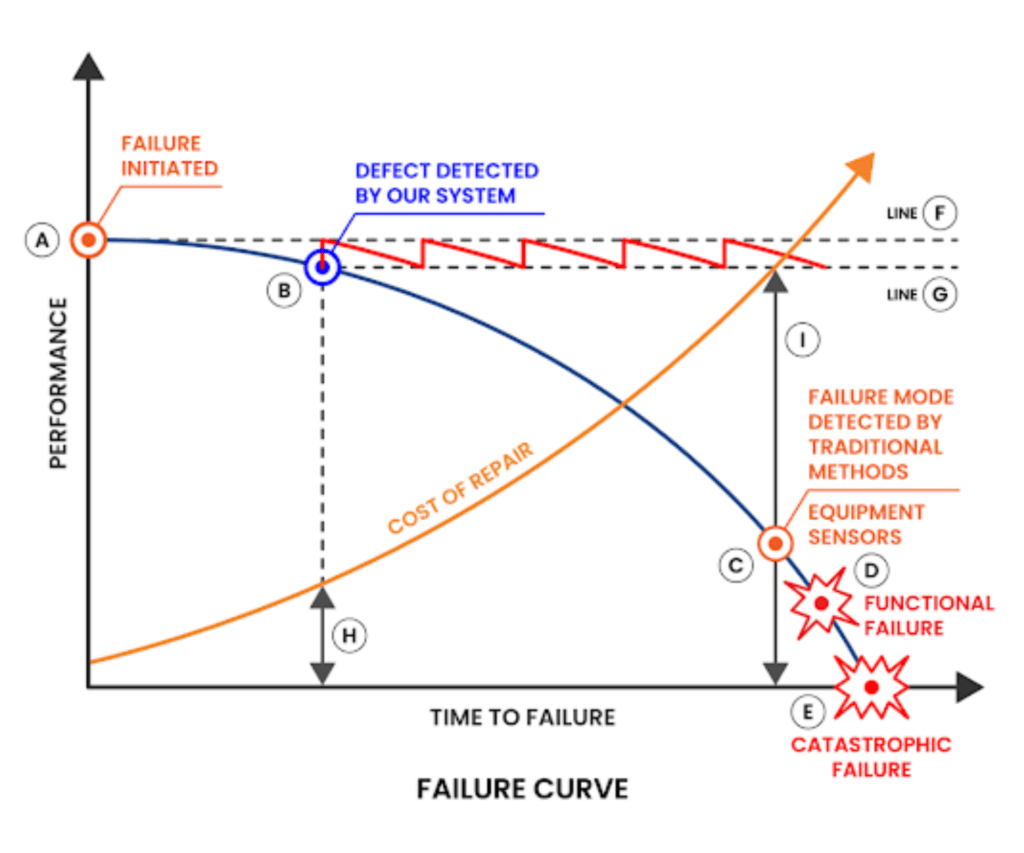

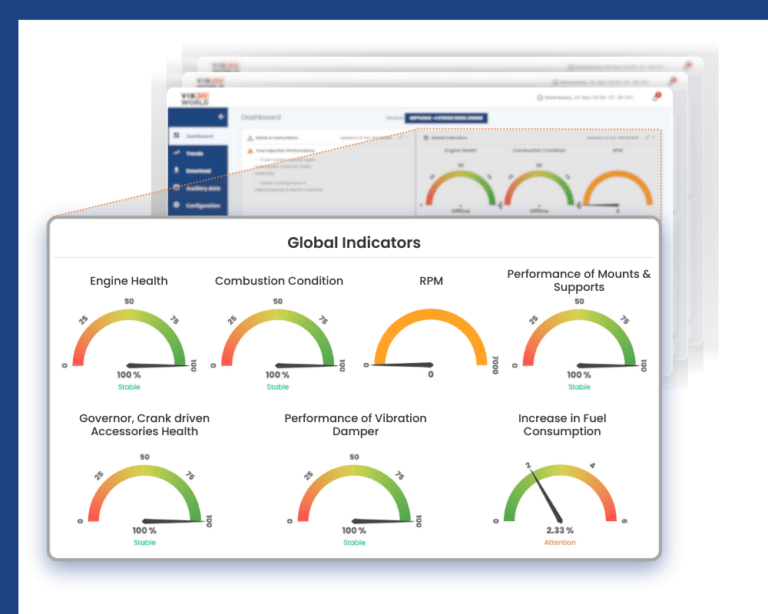

Diesel engine condition monitoring systems offer advanced features such as remote monitoring, predictive maintenance, and fault diagnosis, helping vessel owners and operators proactively address potential issues before they escalate. By continuously monitoring the engine’s condition, vessel owners can optimize maintenance schedules, reduce unplanned downtime, and maximize operational efficiency.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Challenges in Diesel Engine Maintenance

- Irregular maintenance intervals: Diesel engines are often subjected to varying operating conditions and loads, making it challenging to determine optimal maintenance intervals based on traditional time-based or usage-based schedules.

- Undetected wear and tear: Internal components like cylinders, pistons, and bearings can experience gradual wear and tear, which may go unnoticed until a major failure occurs.

- Difficult fault diagnosis: Identifying the root cause of a problem in a complex diesel engine system can be time-consuming and requires specialized expertise.

- Environmental conditions: Marine vessels and off-road equipment operate in harsh environments, subjecting the engines to extreme temperatures, humidity, and contaminants, accelerating wear and tear.

How Does a Engine Condition Monitoring System Work?

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Advantages of Engine Monitoring Systems for Diesel Engines

Avoid Unplanned Shutdowns And Breakdowns.

Shift To Condition-Based Maintenance From Scheduled Maintenance

Achieve Significant Savings In Lifecycle Costs

Reduce The Carbon Footprint.

Overcome The Logistical Challenges Of Procuring Spare Parts And Skilled Manpower.

Take Independent Decisions Without The Need For A Certified Expert.

Interested to Know More? Get on Call with Our Expert for a Detailed Walkthrough Of The Technology

Our Engine Condition Monitoring System is Type-Approved by IRS & ABS

Neptunus engine condition monitoring software solution has received A Type approval from the Indian Register of Shipping (IRS)

- Asset owner can follow more effective condition-based maintenance rather than OEM recommended time-based maintenance

- The IRS-approved system helps in extending the major overhauls

- The solution can guide to do minor overhauls to avoid catastrophic failure and to increase fuel efficiency

- Assets monitored with a class-approved system has a good resale value

Vessels and Industries Benefiting from Diesel Engine Condition Monitoring

Diesel engine condition monitoring systems are widely beneficial across various industries and vessel types, including:

- Marine:

- Construction and mining equipment:

- Power generation:

Key Insights into Diesel Engine Maintenance and Reliability

- With proper maintenance, diesel engines can have a lifespan of 300,000 to 500,000 miles or more. (Source: Cummins Inc.- https://www.cummins.com/ )

- In marine applications, diesel engines can last for 20 years or more with proper maintenance. (Source: Wartsila Corporation- https://www.wartsila.com/ )

- Diesel engine maintenance costs can account for up to 30% of the total operating costs for commercial vehicles. (Source: FleetOwner- https://www.fleetowner.com/ )

- Implementing effective condition monitoring systems can reduce maintenance costs by up to 25%. (Source: Predictive Maintenance for Diesel Engines: Benefits, Limitations and Cost-Effectiveness- https://www.researchgate.net/ )