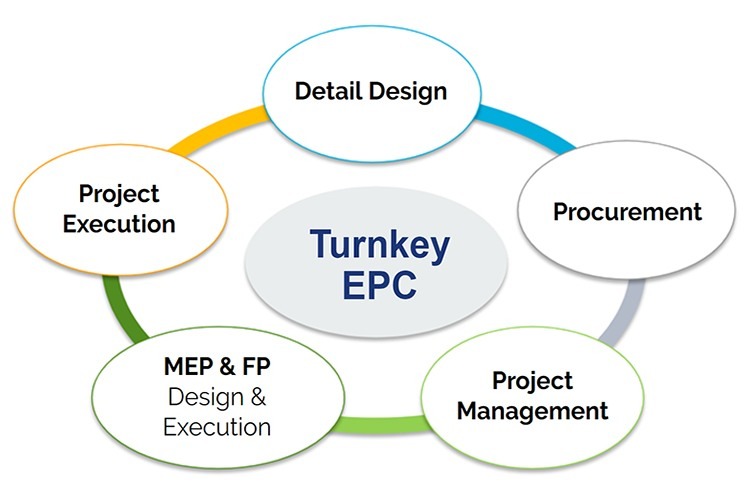

TURNKEY EPC & MEP SOLUTION

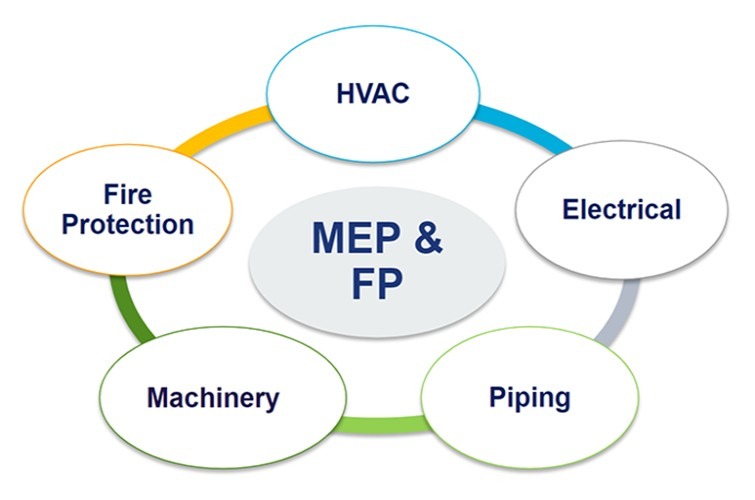

We deliver end-to-end turnkey EPC projects (MEP, HVAC) through reliable design engineering of operator-friendly DG-based backup power plants for Data Centres, Industrial CCPs, Oil Rigs, and Engines Test Cells.

TURNKEY EPC & MEP SOLUTION

We deliver end-to-end turnkey EPC projects (MEP, HVAC) through reliable design engineering of operator-friendly DG-based backup power plants for Data Centres, Industrial CCPs, Oil Rigs, and Engines Test Cells.

Neptunus: Changing The Way Maintenance Is Done

Our Vision For New-Age Design Engineering

At Neptunus, we leverage our insights from over 23 years of experience with diesel and gas engines of various makes and capacities and their applications in data centers, industrial, commercial, marine and oil & gas projects.

We strongly believe in a cost-efficient, environmentally prudent and smarter way to maintain large machinery by combining design engineering with new-age technology to deliver optimized designs that save money, maximizes uptime and OHS compliance

End to End Engineering

Solutions

We have studied engines, machines and DG-sets for over 2 decades, and this has enabled us to be end-to-end design engineering solution providers. From procurement, construction and commissioning of engine-based back-up power plants to MEP, HVAC and designing fire systems for industrial and commercial facilities, Neptunus has in-house certified experts for all things engines. Our Project Management capabilities would ensure we deliver complex engineering projects within agreed timelines, costs and quality to ensure QVC(Quality-Velocity-Cost) always!

Market Track

Record

Neptunus: Changing The Way Maintenance Is Done

Increasing Operational Life

- Operator friendly design layout of critical machinery such as generators

- Lowering operating risk by foreseeing future maintenance needs (eg: removing radiators from generators)

Smart Procurement

- 23 years of working experience across DG-sets of various make

- Designing Tender Specs, BoQ, and techno-commercial evaluation of supplier bids

- Robust negotiations resulting in cost savings of upwards of INR 6-9 crore in high side and low-side package of DG.

Design Optimization

- Lowering the safety hazard of fuel leakage and risk of downtime

- Designing fire safety features: fusible link which melts in the event of a fire and transfers entire diesel to storage

- Isolation of fuel supply lines for individual DGs

Health and Safety Compliance

- Lowering the compliance risk and enhancing the safety and productivity.

- Limiting the “noise” levels due to engine operations within 45 dba max in rooms.

- Noise attenuation with adding noise silencer in the exhaust air duct.

Fuel Management

- Designing a ‘fuel polishing system’ at fuel intake point of storage tanks to minimize fuel contamination

- Lower operational costs and increased engine efficiency by avoiding frequent cleaning of sedimentation in the tank

Neptunus: Changing The Way Maintenance Is Done

Project Management and Commissioning of a 41MW backup power plant for Greenfield Data Centre

Building the world’s first multi-engine, multi-brand engine dyno test cell for Kenyan Navy

Building a 40 MW IPP with diesel-powered engines at Aden - Yemen

Would you be keen to know more about any of our Services?

You can visit here to download more information