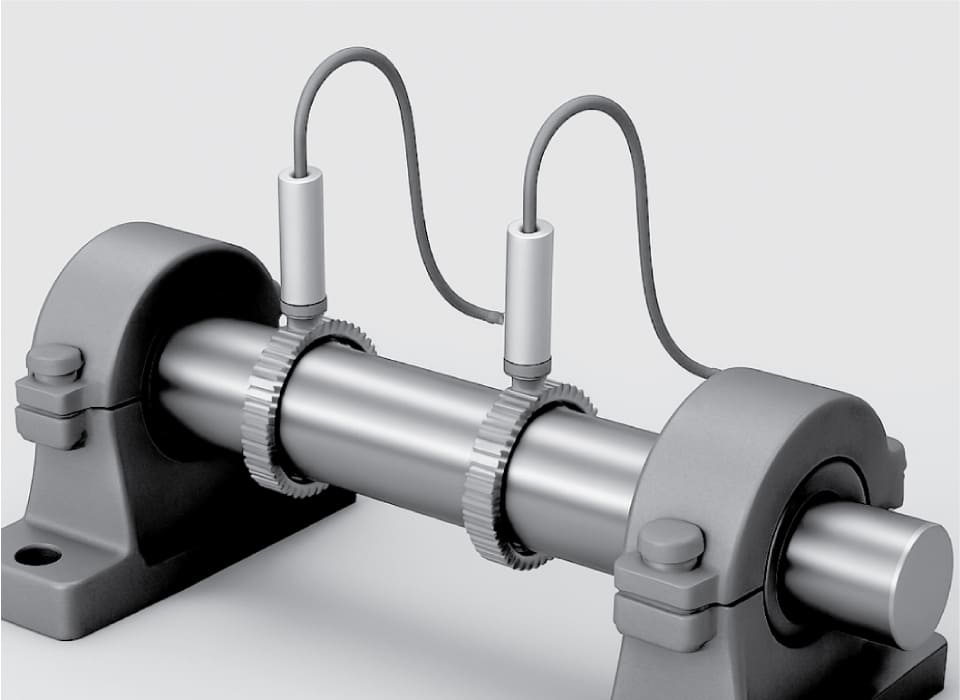

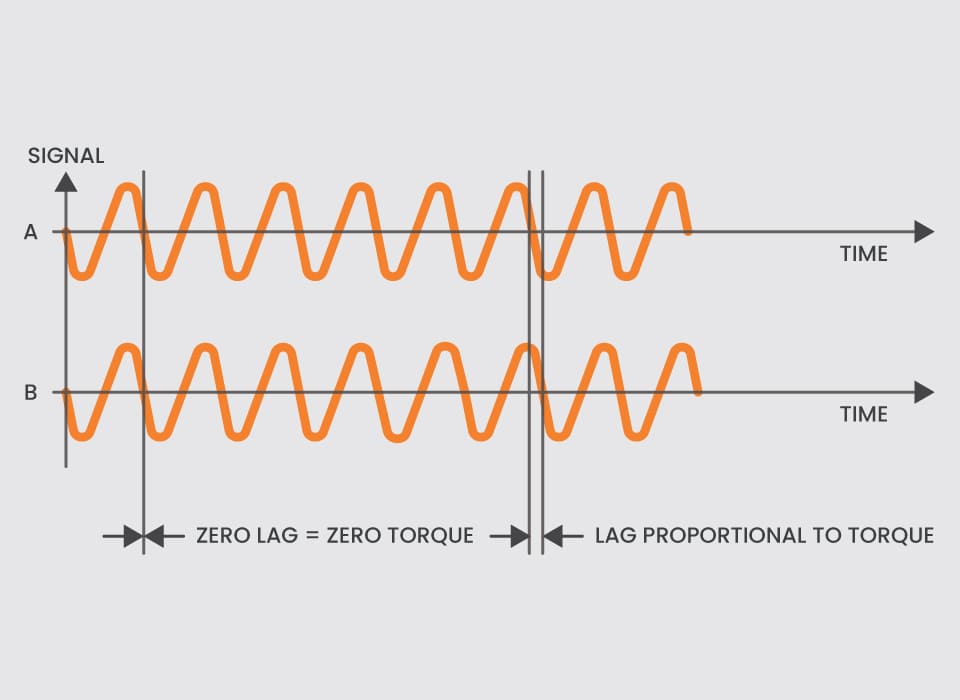

TorqueSense is a cutting-edge solution for real-time shaft power measurement, purpose-built for the demanding conditions of the marine industry. Designed with simplicity and accuracy at its core, TorqueSense uses just two non-contact sensors—eliminating the need for slip rings, shaft-mounted electronics, or strain gauges—to deliver highly reliable torque and RPM data. With its retrofit-ready design, zero maintenance requirements, and class-compliant architecture, the system ensures seamless integration across a wide range of vessels, from harbour tugs to offshore supply ships and naval craft.

Unlike traditional shaft power meters that only measure torque and power, TorqueSense unlocks a broader spectrum of operational insights. It captures and analyses torsional vibrations, shock loads, harmonic frequencies, and shaftline mechanical behaviour. This comprehensive visibility into the entire shaftline health enables operators to identify issues like misalignment or unbalanced loads early on, making predictive maintenance a reality. By monitoring stern tube health and other critical components, TorqueSense adds a layer of intelligence that extends asset life and improves operational safety. Shipowners can now take control of propeller efficiency decisions with actionable, real-time data, enabling data-driven choices that lower fuel consumption, reduce emissions, and drive profitability—making TorqueSense a vital tool for modern marine operations.

More than just a measurement tool, TorqueSense is a strategic asset for performance optimization and compliance. It supports EEXI and CII regulatory requirements by offering accurate Shaft Power Limitation (ShaPoLi) insights and seamlessly integrates with fuel mass flow meters and smart engine analytics.Just two no-contact sensors. No slip rings. No shaft-mounted electronics. No strain gauges.

Only pure, reliable data – with accuracy and repeatability you can trust.

| System Specifications | |

|---|---|

| Shaft Power | 300kW to 90,000kW |

| Shaft RPM | 30 to 3000 RPM |

| Shaft Diameter | 130mm to 800mm |

| Shaft Construction | Hollow / Solid |

| Read Outs / Results | Once in Every 3 min |

| Communication Ports |

|---|

| 1 Gigabit Ethernet Port (10/100/1000 Mbps) |

| 1 CAN 2.0B Port up to 1 Mbps |

| 1 RS232 (EIA-232) Serial Port up to 230 kbps |

| 1 RS485 (EIA-485) Serial Port up to 1 Mbps |

| Hardware Specifications | |

|---|---|

| Operating Temperature | -40° to +75° C |

| RAM | 1GB DDR3L |

| Internal Memory | 64GB |

| Processor | 8GB eMMC |

| Sensor Model | E16S40 |

| Sensor Size | M16 X 1.5 |

| Sensor Operating Temperature | -40° to +125° C |

Neptunus Power Plant Services Pvt. Ltd.

India

Neptunus Main Office

A 554/555, TTC Industrial Area,

MIDC Mahape, Navi Mumbai,

Maharashtra 400710, India.

UAE

Neptunus Global Trading (NGT)

Ras Al Khaimah Economic Zone,

RAKEZ Al Mamourah Street,

Ras Al-Khaimah, UAE.

France

dataVIB Impédance

80 Dom. de Montvoisin,

91400 Gometz-la-Ville,

France.