CAT Engine Rebuild Services

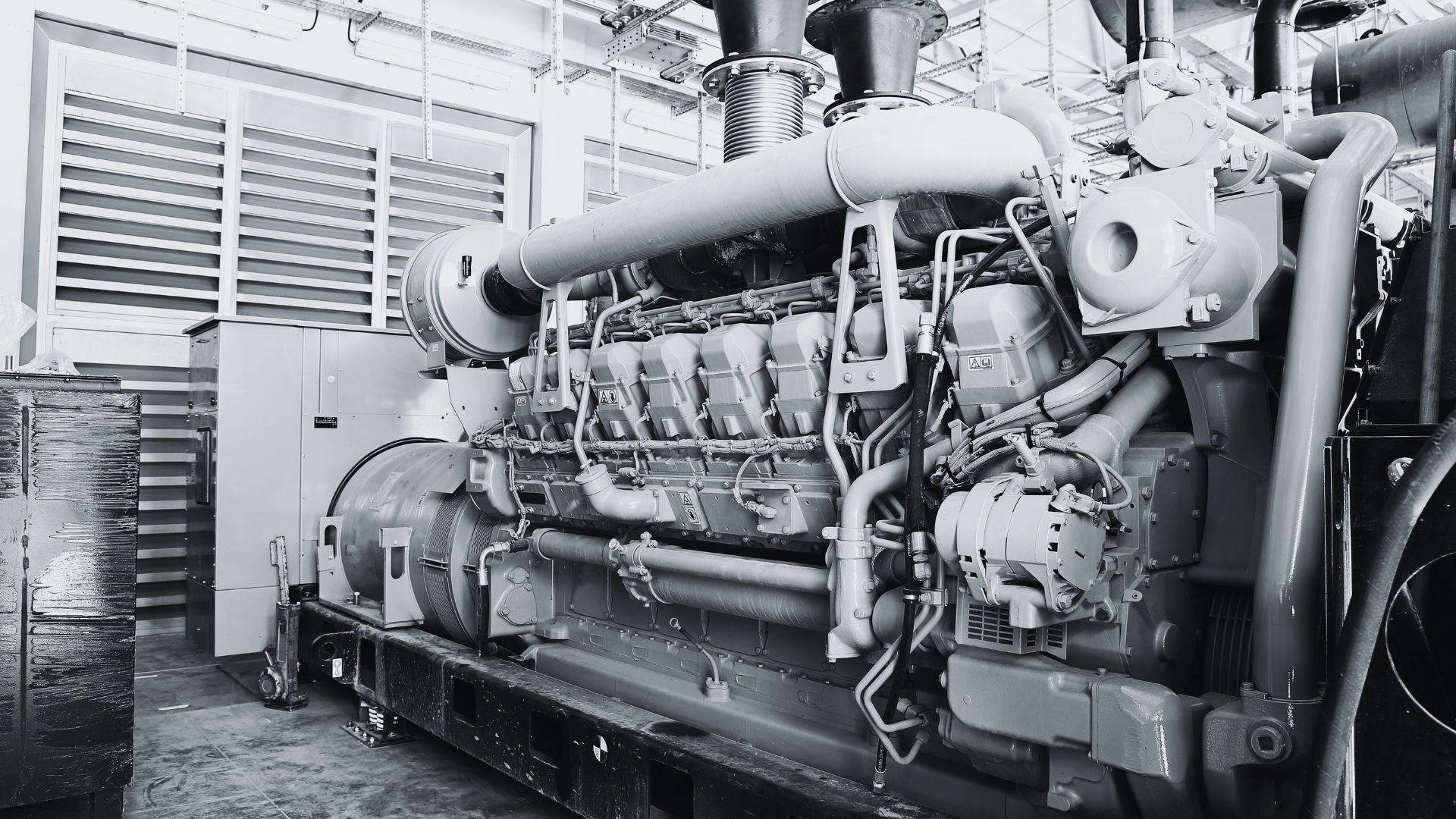

Rebuilding your marine propulsion engine, generator set, or other power system to its original performance and durability levels is crucial for maintaining operational efficiency and reducing downtime. At Neptunus, we specialize in the rebuilding of Caterpillar (CAT) engines, providing comprehensive services that ensure your equipment performs like new. The cat engine rebuilding not only extends the lifespan of your engine but also enhances its performance, making it a cost-effective and sustainable alternative to purchasing a new engine.

We have over three decades of experience in the industry, and we understand the intricate needs of our customers across India, South Asia, the Middle East, Europe, Africa, and beyond. Our team of 27+ highly skilled engineers is dedicated to providing comprehensive Caterpillar engine rebuild services, offering solutions ranging from component-level rebuilds to complete engine overhauls, ensuring reliable and efficient performance for all types of industrial and marine applications.

With strategic presences in key Indian dry-docking zones, including Mumbai, Cochin, Goa, Kolkata, Chennai, Visakhapatnam, and Haldia, we are well-equipped to cater to the diverse requirements of our customers. As an independent service provider of Caterpillar engine repair and rebuild services, we take pride in our ability to provide tailored solutions that meet the unique demands of each project.

With over three decades of experience in the industry and a team of 27+ highly skilled engineers, Neptunus is well-equipped to meet the diverse needs of our customers across India, South Asia, the Middle East, Europe, Africa, and other regions globally. We have established strategic presences in important Indian dry-docking zones, including Mumbai, Cochin, Goa, Kolkata, Chennai, Visakhapatnam, and Haldia, making us readily accessible for caterpillar remanufactured engine spare parts to our clients.

Disclaimer: Neptunus is an independent spare parts and service provider. CAT and Caterpillar are trademarks of Caterpillar, Inc.

Send In Your Enquiry for a Quick Quote

Benefits of CAT Engine Rebuilding Services from Neptunus

Improved Fuel

Consumption of Engine

Reduced

Emissions

Reduced Owning and

Operating Costs

Technology

upgrades

High-Quality

Genuine Parts

Competitive

Pricing

Trained CAT

Specialists

Quick Response to

Your Queries

Optimized Spare Parts

Kits for Overhauls

Shortest Possible Lead Time

for Spare Parts Delivery

Valid Warranty

and Support

Send In Your Enquiry for a Quick Quote

Process of CAT Engine Rebuild

- Inspection/Evaluation:

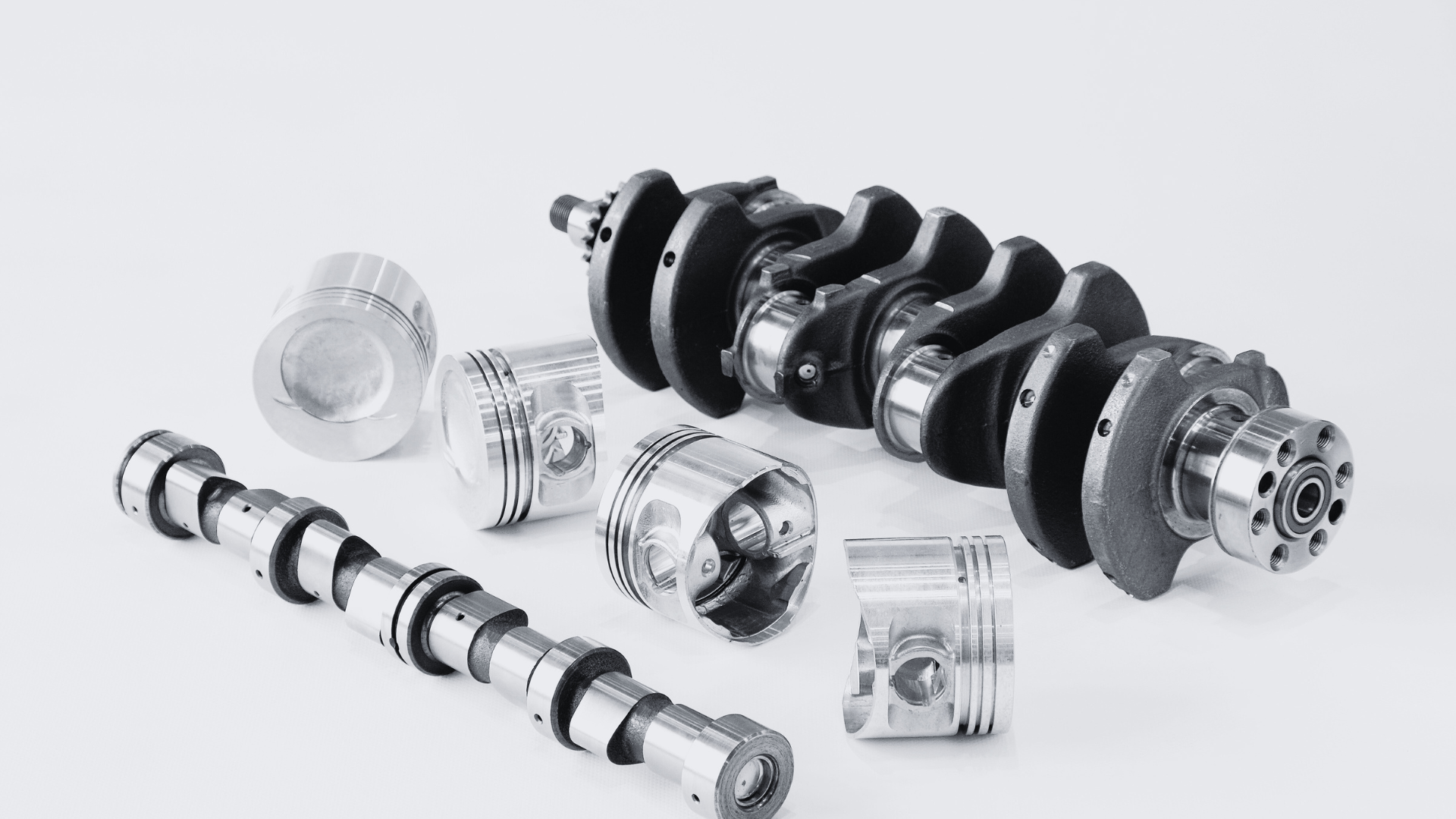

The initial step is crucial, involving a meticulous process where we develop a tailored rebuild plan and cost estimate for your engine. This comprehensive evaluation determines the specific needs of your engine. - Disassembly:

Once the rebuild plan is set, your engine will be fully disassembled. Each part will be inspected and measured against our stringent reusability guidelines. Parts that do not meet our high standards will be replaced with new Caterpillar components. - Reconditioning:

This phase addresses equipment needs that are not typically included in a standard engine overhaul. - Reassembly:

Our skilled technicians will meticulously reassemble your engine, ensuring each component is properly installed. - Testing and Validation:

Following the original commissioning procedures, the engine will be thoroughly retested and re-commissioned to ensure it meets all performance standards. - Handover to Customer:

Once all procedures are complete, we will hand over the engine to you, ensuring it meets the highest standards of quality and performance.

Caterpillar Engine Rebuild Services by Neptunus

Component-Level Rebuilds

Rebuild and recondition individual engine components for optimal performance.

Sub-Assembly Rebuilds

Rebuild and overhaul sub-assemblies, restoring them to like-new condition.

Complete Engine Rebuilds

Comprehensive rebuild and overhaul of entire Caterpillar engines, ensuring peak performance.

Send In Your Enquiry for a Quick Quote

Our portfolio spans these engine models

| CAT D399 | CAT 3406 | CAT C15 | CAT 3500 A |

|---|---|---|---|

| CAT D379 | CAT 3408 | CAT C18 | CAT 3500 B&C |

| CAT 3304 | CAT 3412 | CAT C32 | CAT 3606 |

| CAT 3306 | CAT C7.1 | CAT C27 | CAT 3608 |

Beyond Spare Parts for Your CAT Engine Rebuilt services

At Neptunus, we are dedicated to forming enduring partnerships with our clients by offering asset reliability solutions that go beyond simple CAT engine rebuilds. Our focus is on long-term strategies tailored to your specific needs, rather than short-term fixes. We carefully analyze your genuine requirements and provide customized spare parts.

By leveraging advanced technology, we deliver cost-effective and sustainable solutions designed to maximize the longevity and performance of your Caterpillar engine. Our proprietary engine condition monitoring system, approved by both ABS and IRS, along with our comprehensive in-house oil quality management systems, includes real-time oil condition monitoring system and a continuous kidney loop filtration system. These innovations have significantly benefited our clients. Here’s how we assist our customers:

- Prevent engine breakdowns

- Reduce the cost of engine maintenance

- Reduce Scope 1 and Scope 3 emissions from the engine

If you want to reach similar goals for your organization, schedule a “discovery call” with our specialists to see how we can assist you.

Send In Your Enquiry for a Quick Quote

In addition to our CAT engine rebuild services, we specialise in cat diesel engine repair and offer a full range of options. Our machine repair services include a wide variety, including cat engine repair service repair systems and generator repair. With our skilled team, we guarantee top-notch service and dependability for all of your machinery needs, from engines to propulsion systems and beyond.