Asset Reliability Management Solution

What Is Asset Reliability Management?

Asset Reliability Management (ARM) is a comprehensive approach that ensures the efficient and reliable performance of equipment and other assets within an organization. This involves planning maintenance using predictive maintenance technologies to prevent breakdowns and minimize downtime.

The ultimate goal of ARM is to maximize asset availability, performance, and productivity while minimizing maintenance costs and reducing the risk of failure. By implementing ARM strategies and techniques, organizations can improve their operational efficiency, reduce downtime, and increase profitability.

Importance of Asset Reliability Management

Enhanced

Asset

Reliability

Asset reliability management

minimizes unplanned downtime and ensures optimal performance of critical machines.

Read more

Higher

Machine

Uptime

The ARM maximizes machine uptime and availability, even minimizing disruption to operations. Read more

Better Maintenance Planning

Improve maintenance planning and scheduling, leading to reduced downtime and increased productivity. Read more

A Higher Level Of Customer Satisfaction

By ensuring that assets are reliable and running effectively, organizations can provide better service to their customers, resulting in higher levels of satisfaction and loyalty. Read more

Reduction In Maintenance Costs

This system reduces the cost of maintenance and repairs through predictive maintenance and early fault detection. Read more

Strengthen Operational Safety

It identifies potential safety hazards and prevents accidents through real-time condition monitoring . Read more

Increased

Sustainability

Extend the lifespan of equipment, reduce waste, and promote environmental sustainability. Read more

Better

Decision-Making

Utilize data and insights to make informed decisions on equipment maintenance and replacement. Read more

How Is Asset Reliability Management Done In Neptunus’ Way?

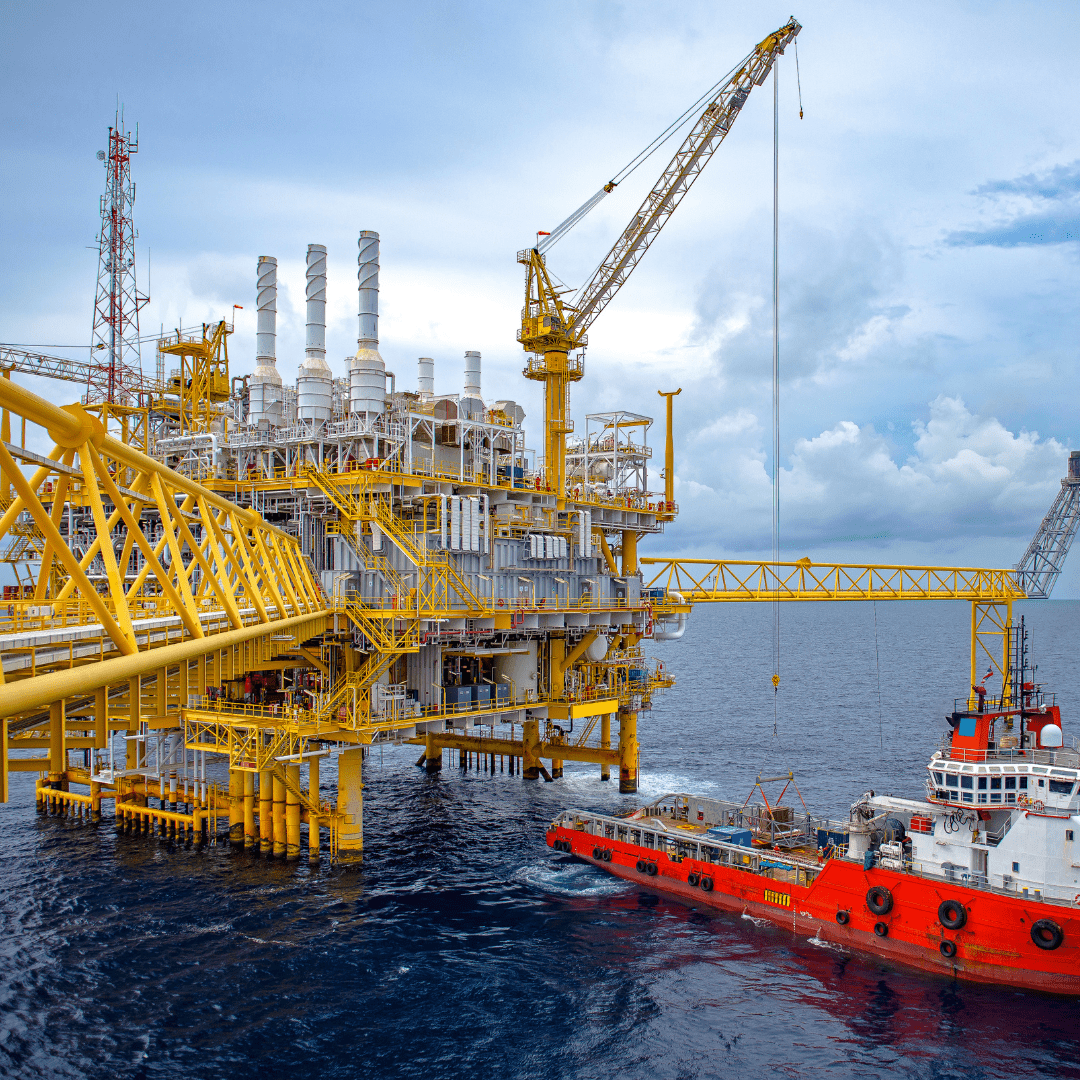

At Neptunus, we pride ourselves on our ability to combine the traditional principles of mechanical engineering with state-of-the-art diagnostic technology. Our cutting-edge solutions empower asset operators to detect emerging faults in their equipment several months in advance. This, in turn, enables them to make smarter, economically and environmentally optimal maintenance decisions that increase both the efficiency and lifespan of their critical equipment.

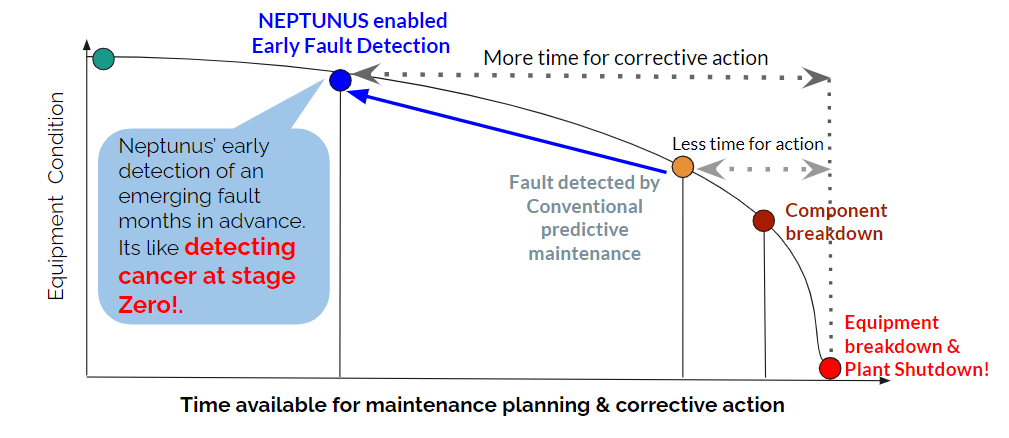

Our ultimate objective is to help our customers move further left on the PF curve, as depicted in the graph below. Neptunus’ asset reliability management solution will enable the detection of emerging faults much earlier compared to conventional maintenance methods such as linear vibration. By doing so, they have more time to take corrective action before the equipment reaches its breakdown point.

Asset Reliability Management Solution At Neptunus

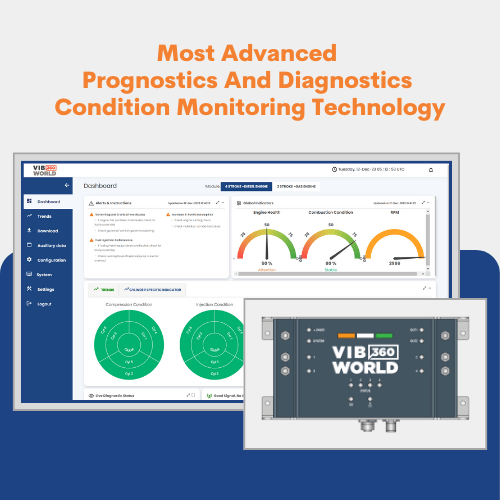

Condition Monitoring System

Condition monitoring is a maintenance strategy that collects data on the machine’s condition using sensors to detect potential issues.

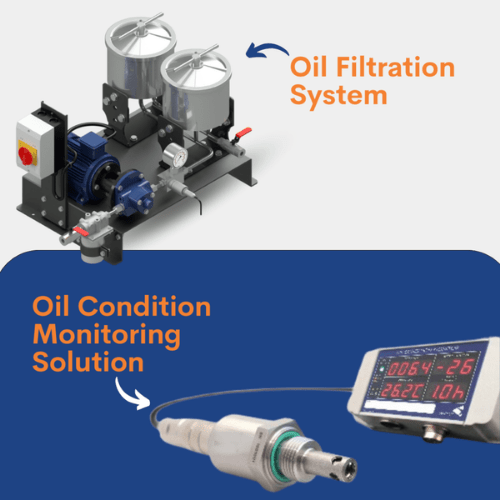

Oil Quality Management Solution

Oil quality management solutions enhance oil and engine performance through continuous oil cleaning with depth filtration and sense oil quality changes in real-time based on 22 parameters

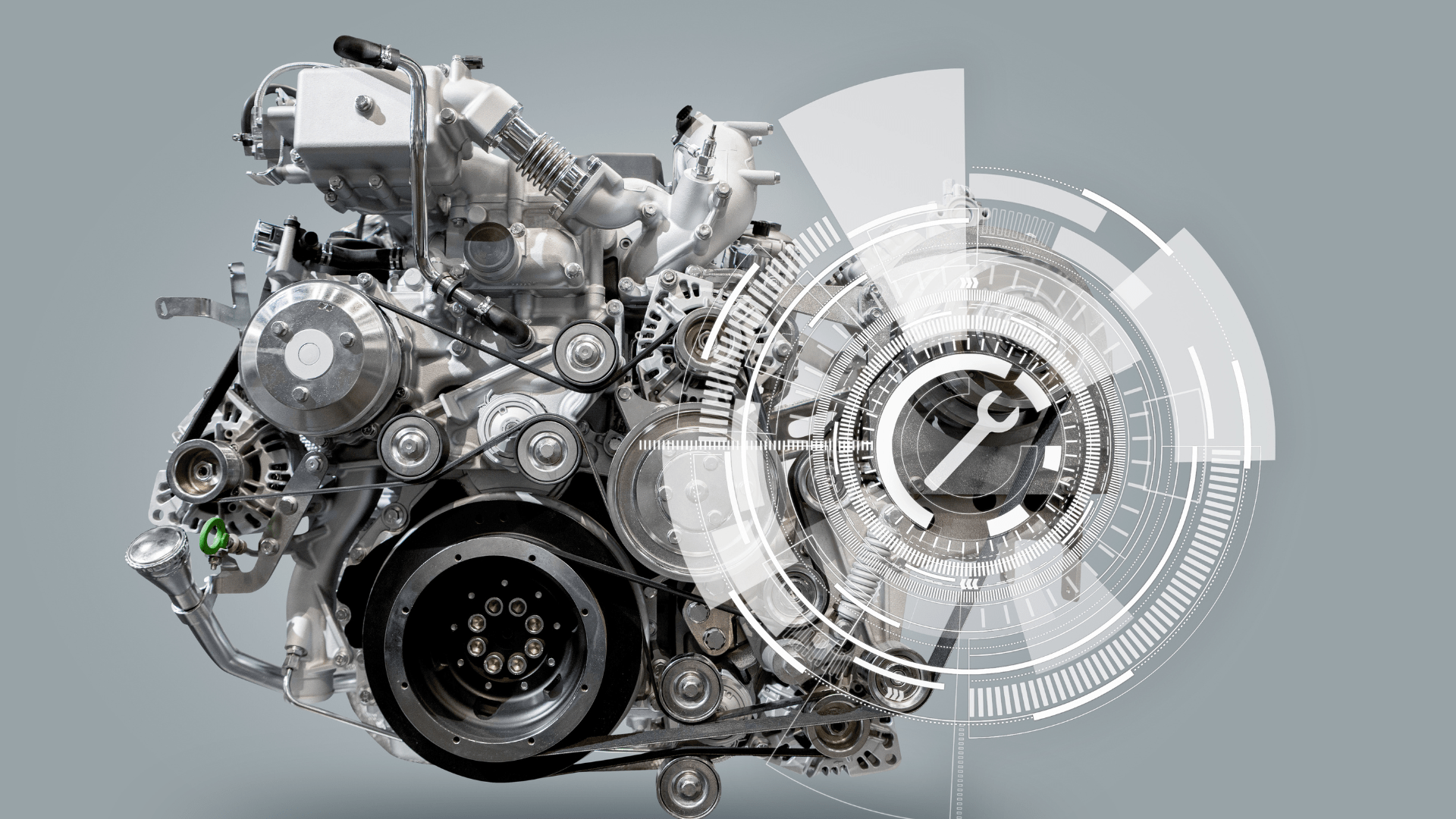

Engine, Propulsions System Maintenance

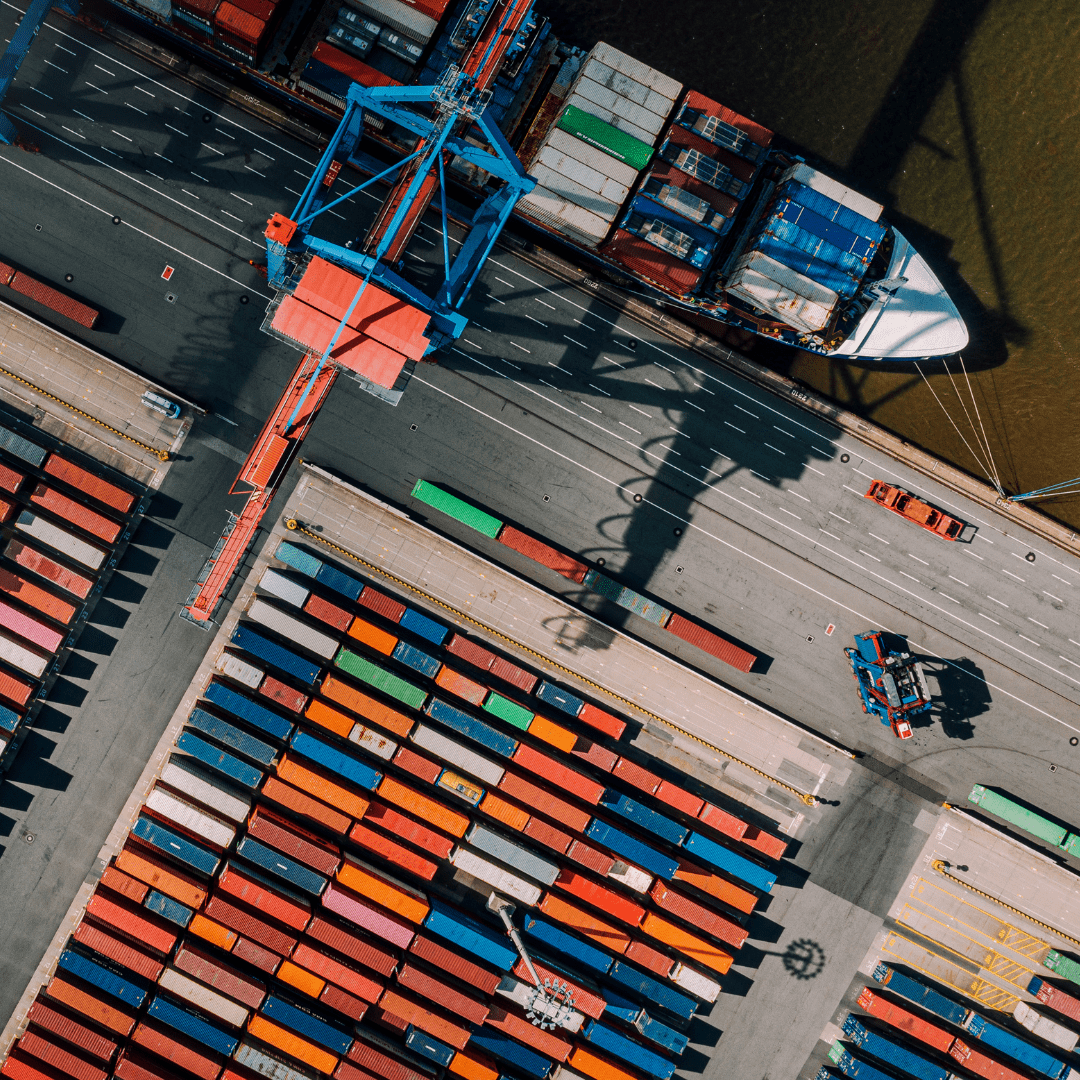

Trusted partner for maintenance, and service of engines, propulsion systems, and auxiliary equipment from leading brands including Niigata (OEM Authorized), EMD (OEM Authorized), CAT, MAN, Wartsila, and Yanmar.

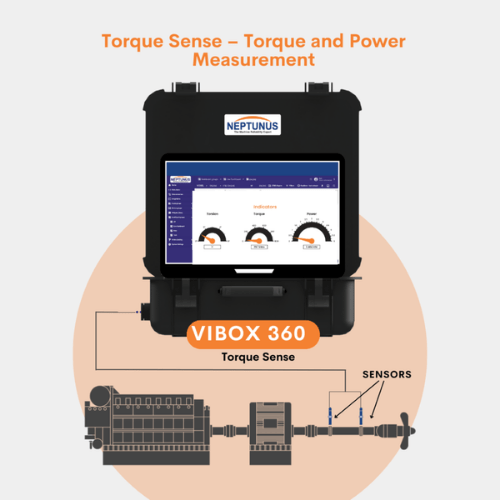

Torque Sense: Torque and Power Measurement

Torque sense offers precise torque and power measurement with unmatched reliability, no speed limits, and enhanced emission control.

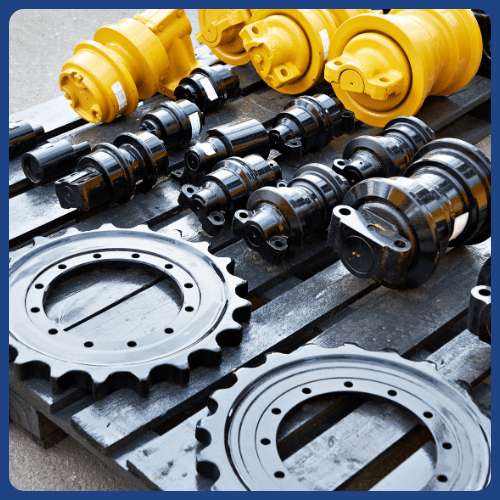

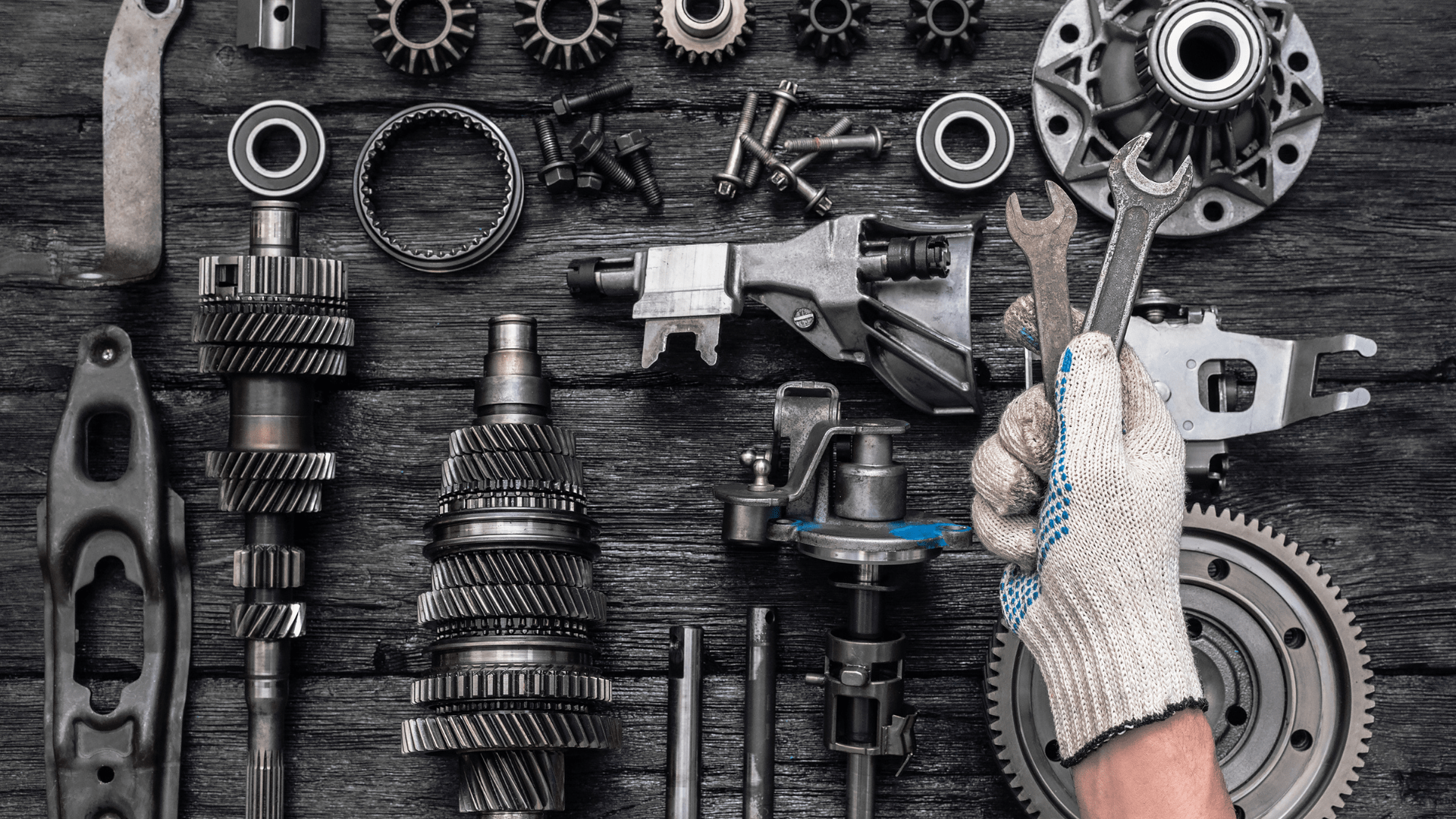

Engine, Propulsions System Spare Parts

Trusted partner for genuine parts for engines, propulsion systems, and auxiliary equipment from leading brands including Niigata (OEM Authorized), EMD (OEM Authorized), and CAT.

Intelligent Maintenance Services

By leveraging our team's expertise and utilizing advanced

technologies, we can help customers streamline their workflows and improve productivity. With a focus on planning and execution strategies, we offer intelligent engine diagnostic, maintenance, and overhauling services.

Read more

Custom Curation of the Spares List

We procure genuine spare parts directly from original equipment

manufacturers (OEMs) or reliable suppliers. Our spare parts list is tailored to your specific needs by using data to create a custom curation that ensures maximum efficiency and cost-effectiveness.

Furthermore, we identify and highlight the most critical spare parts in the list, ensuring that you have easy access to the parts that are most essential for maintaining your equipment's optimal performance.

Read more

Complete

Picture

More data points help you make an accurate prediction.

Torsional vibration and oil conditions are like the heartbeats and blood pressure of the machine. Measuring both gives a correct indication of the machine's health.

Read more

Early

Warning

Our Torsional

vibration monitoring system can give

a very

early indication of an emerging fault. It's like detecting cancer at stage 0 itself rather than later stages. Having more time to take corrective action is the key!

Read more

Adequate Window for Maintenance Preparation

Neptunus' asset reliability management approach allows

for the early detection of faults, which in turn gives customers more time to plan maintenance schedules and take corrective action before any machine breakdowns occur.

Read more

lloT & Industry 4.0

Ready

Connectivity and communication between different systems

are critical for smart manufacturing. The ability to remotely monitor cloud computing is integral to designing solutions for Industry 4.0.

Read more

User-Friendly

Interface

A simplified user interface empowers the operator on the shop

floor to take quick action based on the alarm, rather than relying on human expertise for the analysis of vibration waveforms in lab analysis of oil.

identification of problems.

Read more