Marine Engine Repair and Overhaul Services

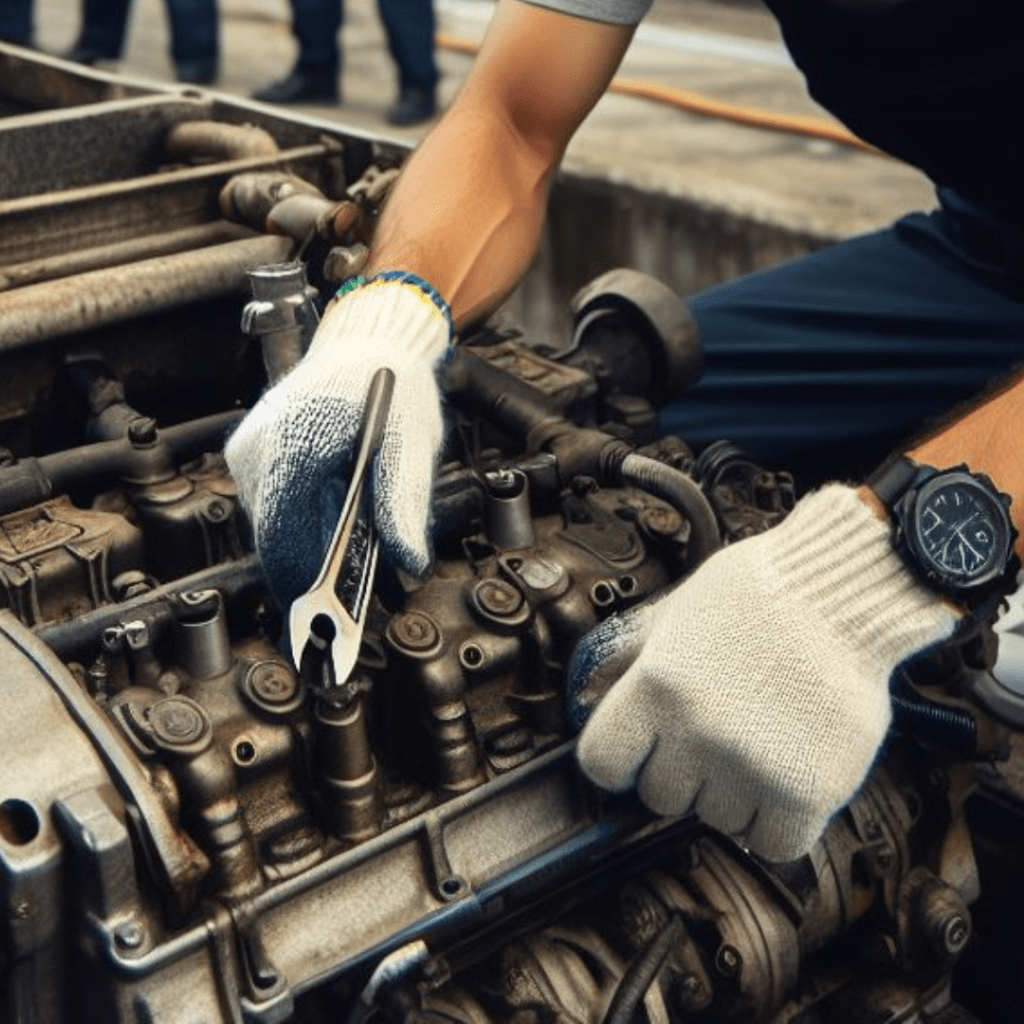

Neptunus Power stands as a renowned provider of comprehensive marine engine repair and overhaul services, catering to the complex needs of the maritime industry. With a team of highly skilled and experienced engineers, we specialize in delivering precise and efficient solutions for a wide array of leading marine engine brands.

With our team of 27+ highly skilled engineers, we specialize in maintenance services for all 4-stroke high-speed and medium-speed engines, along with propulsion systems. Our expertise extends to major overhauls, top overhauls, and a diverse range of main engine repair services, tailored to meet the unique challenges of the demanding marine environment. With over 2000 successful projects under our belt, we are supported by riding squads for efficient on-site assistance.

We offer comprehensive marine engine repair and overhaul services on a global scale, leveraging our extensive experience in catering to clients across South Asia, the Middle East, Europe, and Africa. Our expertise extends to prominent regions within India, including Mumbai, Cochin, Goa, Kolkata, Chennai, Visakhapatnam, and Haldia. With a proven track record of delivering high-quality services, we are committed to meeting the diverse needs of our clients worldwide.

With a focus on delivering tailored services, we offer specialized overhaul and repair solutions for marine engine brands, including Niigata (OEM Authorized), CAT (Independent Service Provider), EMD (OEM Authorized), Wartsila, Yanmar, MAN, MTU, Detroit, and Wuxi. Our expertise extends to engines, ensuring comprehensive coverage for all propulsion system components.

Send In Your Enquiry for a Quick Quote

Challenges in Marine Engine Repair & Overhaul

- Complexity of Marine Propulsion Systems: Marine engines are intricate systems with numerous components, making overhauls and repairs challenging due to the intricate nature of the work required.

- Troubleshooting and Diagnostics: Troubleshooting issues in marine engines demands a deep understanding of both mechanical and electrical systems, as well as advanced diagnostic capabilities.

- Sourcing Replacement Parts: Obtaining replacement parts for marine engines can be logistically challenging, particularly in remote marine environments.

- Strategic Planning: Overcoming the challenges of marine engine overhauls and repairs requires strategic planning, technical expertise, and a commitment to ensuring efficient restoration.

- Access to Specialized Tools and Equipment: Marine engine overhauls and repairs often require specialized tools and equipment that may not be readily available on board or at certain locations, posing logistical challenges.

- Time Constraints: Vessels have strict schedules and deadlines, which can create time constraints for completing repairs and overhauls efficiently without causing significant delays.

Why Choose Us for Marine Engine Repair and Overhaul Services?

Years of

Experience

With more than three decades of dedicated service in ship engine repair and overhaul, our expertise ensures swift and precise diagnoses, leading to efficient repairs and minimal downtime for your vessel's engines. Read more

Shortest Turnaround Time

We prioritize the shortest turnaround time with high reliability without compromising quality, ensuring reliable and efficient overhauls of main engines. Our focus is on swift execution in the shortest possible time without compromising on quality. Read more

Remote and On-Site Support

In addition to on-site marine engine overhaul services supported by our riding squad, we also offer remote support capabilities, allowing our experts to assist you promptly, regardless of your location. Read more

Genuine and Optimized Spare Parts List

We provide genuine ship engine spare parts to ensure the longevity and optimal performance of your engines. A technical expert assesses your actual spare parts requirement and suggests optimizing it as much as possible, rather than suggesting a laundry list of spare parts from A to Z. Read more

Utilization of Advanced Technology

We leverage the latest and most advanced tools and technology to ensure accurate diagnosis and efficient execution for your marine engines. Our commitment to utilizing cutting-edge solutions guarantees precise assessments and swift resolutions, maximizing the reliability of your engines. Read more

Send In Your Enquiry for a Quick Quote

Steps in Engine Overhaul

Step 1: Initial Assessment

The diesel engine overhaul starts with our team's initial assessment, allowing us to create a targeted plan addressing specific concerns and optimizing resources for an efficient process.

Step 3 :Cleaning and inspection:

With the marine engine disassembled, our team cleans all parts, revealing hidden issues, gauging wear, detecting corrosion, and identifying potential damage not visible externally. This process helps prevent premature failures.

Step 5: Assembly

The engine is reassembled with precision, ensuring all parts fit and function correctly.

Step 7: Quality Assurance

Finally, quality control checks ensure the overhauled marine diesel engine meets quality norms before delivery. This quality assurance process reaffirms our commitment to providing customers with a thoroughly renewed engine that matches expectations.

Step 2: Disassembly

Following the initial ship engine assessment, our technicians systematically disassemble the entire unit for visual inspection, accurately pinpointing worn or damaged parts. Detailed documentation ensures streamlined reassembly later.

Step 4: Component Refurbishment: Assembly

Post-inspection, we refurbish or replace worn engine components, restoring them to optimal condition. This enhances the marine diesel engine's overall reliability and efficiency post-overhaul.

Step 6: Testing and Calibration

Operational and load testing under variable marine conditions allows our technicians to calibrate and fine-tune the overhauled diesel engine to meet efficiency . The engine testing processes validate the intended engine performance post-overhaul.

Beyond Repair and Overhaul for Your Marine Engine

With our asset reliability management services, we believe in building long-lasting partnerships with our clients, going beyond short-term projects to provide customized solutions. By understanding their needs, we work towards their goals of improving operational efficiency. Our expertise lies in overcoming maintenance challenges with cost-effective, reliable, and sustainable methods, using the latest technology.

Today, with the use of our proprietary, dual-class (ABS and IRS) approved condition monitoring system for engines and our in-house holistic oil quality management , solution, which includes a real-time oil condition monitoring system , a continuous kidney loop oil filtration system , we have helped our customers in the in the following ways

- Saving anywhere between ~$20,000 and $60,000+ in engine overhaul costs (around 30% savings).

- Preventing unexpected downtime.

- Enhancing fuel combustion efficiency.

- Reducing and offsetting carbon emissions to meet your ESG objectives.

- Complying with the IMO’s EEXI Regulation.

- Improving maintenance planning, especially for assets situated in challenging locations.

If your company aims to achieve similar milestones, schedule a “discovery call” with our experts to learn how we can assist you.

In addition to our main engine services, we specialize in auxiliary engine service, providing a complete suite of solutions for the marine and oil & gas industries. From diesel generator repair , to marine propulsion services , our marine engine experts ensure top-notch service and reliability for all your machinery needs.